Courtaulds is an international chemical company with annual sales of more than £2 billion, employing 17,000 people in 45 countries worldwide. It developed from a small silk weaving business in England in 1816 and became well known in the early part of this century after pioneering the mass production of viscose rayon. This first man-made fibre has played a vital role in the textile and non-wovens industry and it continues to be a major material for manufacturers around the globe.

Acetate yarns and fibres followed the introduction of viscose, with Courtelle acrylic fibre being launched in the 1950s. TENCEL represents the latest in a line of products from this famous heritage. Courtaulds also manufactures coatings – its International Paint brand is a world leader in the marine and yacht market – and most of the world’s airlines and aircraft manufacturers use the company’s aerospace coatings and sealants. Its engineering business designs and builds production plants and equipment throughout the world.

Courtaulds also makes polymer products for such end uses as toothpaste tubes, medical applicators and performance films for high technology industrial end uses and solar control applications on windows. Its chemicals are supplied to a range of industries, including the packaging, photographic, cosmetic and pharmaceutical markets.

What is TENCEL?

As consumers, we identify products in different ways. Branding involves developing features which identify a range of products. TENCEL is Courtaulds brand name for a fibre known generically as lyocell, produced via a revolutionary solvent spun cellulose-based technology. This technology is a development of the traditional process which converts natural occurring cellulose (woodpulp) into material to be used for many different applications and is of major significance to the world’s fibre industry. It is unique not only because of the production process but because of the combination of properties it offers to the world of fashion. For example, its strength means TENCEL is the first fibre, after cotton, that has been used to create authentic denim.

Products are not just developed to meet a single need. The ownership and use of a product involves a whole range of factors that make up the product concept. For example, modern products have generic dimensions comprising key benefits, sensual dimensions such as design, taste or colour and extended dimensions providing additional benefits. On its own or in blends, TENCEL provides tangible benefits for both spinners and weavers through to garment manufacturers, high-fashion designers and the consumer.

For textile manufacturers, it offers the strength to withstand the most demanding of spinning, weaving and knitting processes. It demonstrates strong dye uptake and provides natural, bright vibrant colours on piece dyed or printed fabrics. In addition, TENCEL is being used to make fabrics which are new to the fashion industry, allowing finishers to demonstrate their skills to the full. The results give the designer an aesthetic range second to none. Its strength and versatility make it ideal for blending with materials such as cotton, wool and silk and with other fibres such as Lycra, polyester and nylon. For the wearer, TENCEL garments do not diminish through wash and wear and, in common with other cellulosic fibres such as viscose and cotton, they are immensely comfortable to wear throughout the seasons, because TENCEL ‘breathes’.

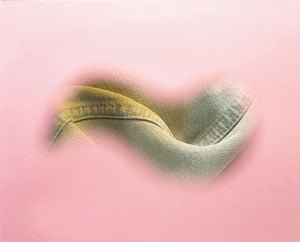

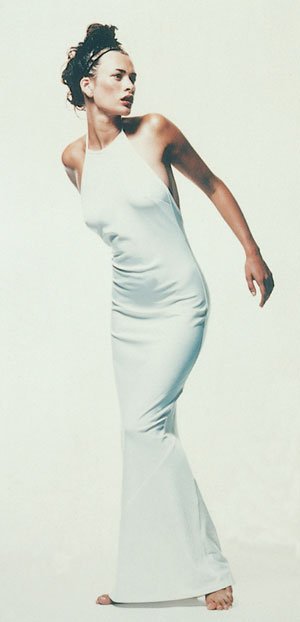

TENCEL lends extraordinarily surprising touch and feel aesthetics to classics – such as the chambray style developed in Europe, which retain the authentic look, yet exhibit remarkable fluidity – and feel uniquely soft and smooth. TENCEL is capable of satisfying a whole range of fabric needs from fine fashion ladies’ lightweight blouses and dresswear through to moderately heavy skirtings and men’s and women’s suits, jackets, blazers and sportswear.

Developing a unique fibre

In the world of fashion there is a clear link between the tastes of consumers for materials and garments and the demand for the type of products on offer. Though particular clothing fashions may change not only with the seasons but also from year to year, the materials making up such garments will have a longer product life-cycle. A product life-cycle tracks the lifetime of a product from development through to maturity. Students who take more than a passing interest in the world of fashion will be familiar with a remarkable new, natural material which began to attract attention on the catwalks back in 1992.

It has been described as the chameleon of fashion – a fibre that feels as soft as velvet yet is stronger than cotton is comfortable, washable and looks and performs like silk when in fabric form. Its name is TENCEL. It has been developed by the British-based international chemical group Courtaulds, who pioneered viscose rayon, and it is the first new man-made fibre for 30 years.

TENCEL made an immediate impact on the market. It was positioned as a top-of-the-market product. Early recognition by leading designers and fashion houses included some of the best known brand names such as Calvin Klein, Joop!, Georges Rech, John Rocha, Armani, Lacroix, Jean Paul Gaultier and Paul Costelloe. Ferré and Cerruti are also among the fashion icons working with the new material.

Proactive development

The development of TENCEL is an example of Courtaulds initiative in the market-place. Proactive product development involves taking the lead in a market with the launch of innovative products which are completely different from those of competitors. TENCEL’s development from research project to a fibre with sound environmental credentials, destined to be the apparel material of the 21st Century, is a story stretching over a period of many years and involving chemists, engineers, designers and a host of other specialist experts working for Courtaulds and the textile and clothing industries.

This case study focuses upon the translation of an idea into a highly marketable product.

• TENCEL is the trademark for Courtaulds Fibres’ lyocell fibre in certified fabrics and garments.

Research and development

Courtaulds created TENCEL as a result of its search for a new high performance cellulosic fibre to be produced by an environmentally favourable process. The first research work began in 1978 and the development journey through to end product marks a truly international achievement. The research took place in the UK, mainly in Coventry but also in Grimsby where limited quantities of the new material came on stream in 1988. Commercial sales followed later that year.

The first full scale production plant was commissioned in the USA in 1992, and Japan was the country where the product’s qualities were first recognised and marketed. Novel techniques were employed to introduce TENCEL garments into some of Japan’s more exclusive high street retailers. These included special garment wash finishing treatments designed to create very soft flowing aesthetics in casual wear.

After Japan, other markets opened up in the USA and Europe. More recently TENCEL has moved into South America and other Asian Pacific countries. Today TENCEL is being retailed in 31 countries worldwide.

Targeting large stores

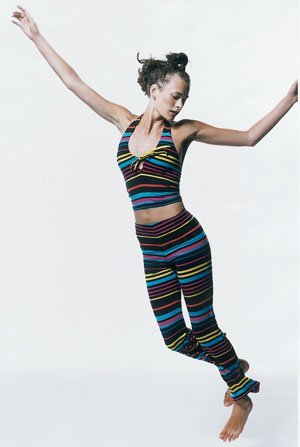

TENCEL was initially introduced to the market via a select group of weavers, dyers, finishers and designers, targeting the casualwear and sportswear sectors of the market. Targeting involves identifying a market segment and then developing a marketing mix which is geared to the needs of customers in that segment. The emphasis was on 100 per cent TENCEL products but, as its versatility became increasingly recognised, TENCEL-rich blends with natural fibres such as wool, cotton, linen and silk were developed.

Prices were relatively high in the early days, but TENCEL garments are now available in many UK high street stores such as House of Fraser, Marks & Spencer and Next. In America, shoppers can buy their TENCEL clothing at Saks, Macy’s and Bloomingdales and in Japan prestigious outlets such as Mitsukoshi stock the material. TENCEL quickly gained a high level of acceptance because of its luxurious, soft and comfortable feel – truly a modern fibre, representing harmony between technology and nature.

The environment and TENCEL

The cellulose used to make TENCEL comes from a special grade of wood pulp, harvested from managed forests. As TENCEL is made from natural cellulose it is ecologically sound and fully biodegradable. Cellulose, the chief constituent of plant cell walls, is produced by all plants and is the world’s most abundant organic material.

TENCEL is a ‘cellulosic’ along with linen (made from flax) and cotton (from cotton plantations). They are all from the same natural fibre family. It took a decade to perfect the TENCEL production process, using the best available technology, and it represents a breakthrough in the way cellulosics are made.

The TENCEL process creates little waste as a result of its advanced ‘closed loop’ spinning process. Its organic solvent is constantly recycled and the whole production method has been accredited with the European Eco-tex certification. TENCEL is a fine example of nature and technology working in perfect harmony to produce an outstanding fibre which gives garments a distinctive touch.

Characteristics of TENCEL

TENCEL can be textured or smooth, rugged or refined, in pure form or blended, in indigo or a range of different colours:

- Touch and feel: its tactile nature is a unique selling point.

- Movement and fluidity.

- Weight and bulk: as winter or summer garments, it is light and pleasing to wear.

- Machine washable: many fabrics in TENCEL are machine washable without losing their aesthetics.

- Crease recovery: it is often better than traditional fibres in regaining its fresh look after creasing.

One of TENCEL’s most important physical properties is fibrillation where, through controlled abrasive action during the wet finishing or garment dye process, the fibre develops micro-fibrils or small hairs on the surface.

The manipulation of these micro fibrils can be engineered to produce versatile and unique aesthetics, such as peach skin or classic suede effects. Fibrillation is the key to the feel and look of TENCEL; a process which allows the material to appear in more guises than any other previous fibre.

Marketing strategy

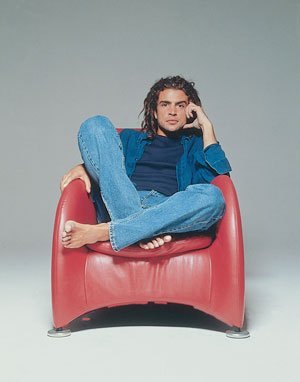

TENCEL has been targeted at fashion range builders and selectors who, via expert spinners, weavers, knitters, dyers, finishers, printers and designers, supply textiles to a variety of outlets. Its combination of fibre properties makes it ideal for end-uses not previously open to man-made cellulosics – such as soft touch denim jeans, chambray shirts, shorts and yarn-dyed colour woven blouses and skirts.

The marketing of TENCEL is supported by promotional, technical and product development activities from Courtaulds, all of which are designed to foster partnerships throughout the textile chain. Known in the business as ‘push-pull’ marketing, it has resulted in the formation of a circle of enthusiastic authorised TENCEL users exploiting the special attributes of what so many people are calling the new wonder fibre. The strategy involves the ‘pushing’ of the product along the textile industry chain to finished fabric level and then ‘pulling’ through the finished garments to consumers by creating desire and demand through promotional activities.

An example of this strategy in Japan is the TENCEL KAI, a grouping of spinners, weavers, knitters, dyers, printers, finishers, garment laundries and fabric wholesalers committed to a set of business principles in the development and promotion of TENCEL to the Japanese apparel industry. Product positioning involves using the marketing mix in a way which takes into account the thoughts and perceptions of consumers relative to other products and brands. TENCEL has been positioned with well-known designers and up-market niche brands embracing sportswear and more formal styles. As new fabric developments are commercialised, it is clear TENCEL’s potential will be exploited still further.

How TENCEL is made

Amine oxide solvent dissolves the wood pulp into a viscous solution. After filtration, the solution is extruded to yield fine filaments, from which the solvent is removed by washing. Virtually all the solvent is recovered and recycled. The resulting fibrous tow is dried and cut to staple fibre. The product is then baled and delivered to spinners in Europe, Africa, Asia and the Americas.

Conclusion

Courtaulds was the first company in the world to produce lyocell staple fibre commercially and by 1996/97 the demand for its branded fibre, TENCEL, was such that the entire output around the world has been sold. Although initial quantities reached the market from a small pilot line in Grimsby, the company’s first full scale plant costing $90 million opened in Alabama, USA in 1992. It was followed by a second $140 million line on the same site in 1996 and the retrofitting of new technology in 1997 boosted the combined capacity of the two lines to 55,000 tonnes of TENCEL annually.

Also due for completion at Grimsby by the end of 1997 was the first European TENCEL plant, a £120 million factory capable of producing 42,000 tonnes annually. With the latest announcement of a third plant to be built for the Asia Pacific markets, Courtaulds expects to achieve a total worldwide annual capacity for TENCEL exceeding 150,000 tonnes by

2005.

This case study illustrates how product development by Courtaulds has been translated into a new fibre brand within a highly competitive global market. Its contribution has provided significant opportunities for designers and fashion houses to develop innovative products for consumer markets. Such investment has allowed Courtaulds to further its business strategy objectives by creating new and improved products for the market-place into the next century, designed to satisfy the changing needs of its customers.