Corus is an international metals company. In 2005 it was the eighth largest steelmaker in the world. The company has an annual turnover of £9 billion.

The company has four divisions and a global network of sales offices and service centres. The global steel industry is highly competitive with a number of large businesses. Corus has major steelworks in the UK located at Port Talbot, Scunthorpe, Teesside and Rotherham.

Continuous Improvement

In 2004, under the new Chief Executive Officer, Philippe Varin, the company launched its Restoring Success programme aimed at closing the competitive gap between Corus and its European competitors. The objective was to make Corus more competitive and to ensure the business became more resilient to any cyclical downturn in the steel industry at times of economic difficulty.

Steel goes into many manufacturing and construction products with demand being sensitive to economic growthand decline. Part of the plan involved cutting back on waste and unnecessary copying of activities and by the end of 2004, 50% of the target savings had been achieved. As a result the company moved into profit last year for the first time since its formation in 1999.

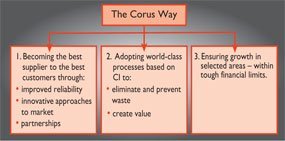

Looking beyond the original ambition of Restoring Success, in 2005 Corus began to develop a programme to create real value in steel, within a safe and sustainable environment – The Corus Way. It comprised these key business goals.

This case study centres on how CI lies at the heart of The Corus Way, and how these goals are achieved by the commitment of an involved, motivated and skilled workforce.

CI has become a common feature in modern business life since it was popularised by Japanese industry, where it is known as ‘Kaizen’. The goal is to improve processes and products over time, taking care to maintain improved performance levels while seeking out further opportunities for improvement.

Introducing CI means changing the culture of a company, which means that members of the organisation are challenged to change their behaviour and upgrade their work. Typical changes will include:

- cutting out pointless activities

- making products and carrying out processes more efficiently

- making processes common and consistent throughout the business.

CI involves the related idea of ‘lean manufacturing’. This simply refers to the removal of waste. If wasteful activities are removed, employees are able to work smarter.

Working in a smarter way does not involve working harder. Smart work involves spending time carrying out processes that create value for customers. The best people to identify ‘lean’ processes are those who are most involved in production activities. This is why Corus places so much importance on involving employees in CI and puts customer requirements at the heart of its business, thereby creating an ongoing culture of improvement.

Top-down committment – The Corus Academy

Implementation is the process of putting plans into action. Having a belief that CI is the way forward is good but the next step is to create the means to achieve it. To implement CI in a consistent way across Corus’ four divisions which contain over 20 different units and functions, co-ordination was required from the top.

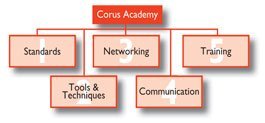

A ‘virtual’ Corus Academy was set up in April 2005, led by a steering group of executive directors, together with a smaller Implementation Group. The Academy provided an enabling structure combining technology, experience and expertise. This encouraged an open learning environment, based on sharing best practice and maximising the use of common approaches. The Academy is split into five work areas.

As Corus is a global company, it needs to communicate internationally and this is where virtual learning is helpful. Examples of best practice can be conveyed in electronic format and shared in databases across the entire organisation. For example, a Corus plant in the Netherlands or UK can learn from the practice of improvements in similar processes in Canada or the United States. CI activities at the Duffel aluminium products plant in Belgium learnt how to more effectively remove waste from the Cap-de-la-Madelaine plant in Canada.

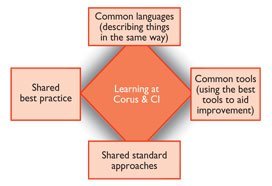

The Academy provides a means of sharing knowledge. Best practice leads to common methods across the businesses. In this way Corus has become a learning organisation. Constant improvements are made through the sharing of ideas across the entire company. There should be no barriers to contact. Learning at Corus, and hence CI, comes from using common language and common tools and sharing best practice and standards.

Learning within the company is achieved through opening communication channels. It also occurs from encouraging everyone to become involved by suggesting and applying changes. This is best achieved when a shared language is used to discuss issues. There are common tools, such as shared databases. In addition, all parts of Corus work together to share examples of best practice. This is so that common approaches can be developed, with best practice being regularly updated in line with improvements.

Corus saw that training was the underlying imperative which would drive the CI process. There was a need to train senior managers to raise awareness and to develop a team of CI coaches to bring about the required changes. An initial target of 250 CI coaches was set across the company as a whole, who in turn would provide the training for the entire workforce to ensure effective implementation.

The lead role in training was placed in the newly formed department of Corporate Training and Learning. This was a central function created to assist the effective implementation of corporate initiatives. In April 2005, the Academy was launched and CI began in earnest at Corus.

Training and development

Following the initial awareness sessions for senior managers to ensure buy-in to CI and to support effective implementation, the key task was to recruit and train the team of CI coaches.

To get 250 CI coaches fully trained and operational would take around two years. To assist this process, Corus signed an agreement with the lean consultancy firm of SA Partners, who had a solid track record of providing benefits to a number of Corus businesses. The company also had a strong bias towards engineering and manufacturing, appropriate to Corus operations.

It takes 29 days to train and develop a fully operational coach. To become certified, an individual has to complete the full course. This is to ensure they absorb the course content but is also vital in guaranteeing a consistency of approach worldwide.

Training involves improving the knowledge, skills and potential of employees. It helps them to provide a more meaningful input into the business. Development goes even further, since it focuses on the needs of the individual as well as those of the company.

CI centres on both training and development and employees are encouraged to become involved with the CI programme and most do so. CI enables them to grow in a variety of ways, by taking on more responsibility and becoming involved with teamwork and team building. Improving knowledge and skills enhances career opportunities.

The aim of CI at Corus is defined as being:

‘to maximise the effectiveness of operational processes and the interface between man and machine to ensure:

- zero product wasting defects

- zero equipment breakdowns

- elimination of unexpected adjustments

- improved working and safety conditions.’

In training sessions, CI coaches are introduced to a range of concepts relating to it. The training manual shows the thinking behind CI. It illustrates a drawing with the question ‘How do you eat an elephant?’ The answer is ‘Bit by bit.’

At the sessions, coaches are given a range of issues and problems ranging from real work observations to case studies. They are asked to identify ways of making good changes. Working through these exercises enables them to see that the best way of securing progress is firstly to define customer needs. Other tasks teach them the value of erasing waste and blockages in production processes.

Of course, CI at Corus is not just about making manufacturing more efficient. It relates to every process the company is involved in, including market research, sales, public and human relations and many other areas.

The CI coaches being trained are the champions of CI. They pass on the message to the rest of Corus’ employees. They are able to communicate the value of teamwork and empowerment. Corus employees operate in a teamwork structure. Members of the teams are asked to suggest areas for enhancement in work practice and processes. Empowerment is the process of giving more responsibility for decision making to individual team members.

Implementation – Corus business cases

There are now many excellent examples of CI in action throughout Corus worldwide.

The Kalzip team at Haydock began its CI programme by improving material flow. To enable this to happen the team moved big machines, such as a nine metre guillotine with a six metre production foundation, relocated welding bays and re-routed workshops. External contractors estimated the job would take eight months. It actually took 2 months with in-house help.

The changes were implemented after detailed value stream mapping discovered a lot of ‘work in progress’ (unproductive activity) as well as potentially unsafe ways of working.It was taking the forklift truck 45 minutes to reach one steel coil as it had to move many others out of the way. Reorganisation of the coils into a new racking system has doubled storage capacity.

The Port Talbot strip products site has also taken on CI with many ensuing benefits. It was estimated that one man was spending 39 weeks a year looking for spare parts. This related to a pilot project at the central engineering workshop’s bond stores. Engineering spare parts, gearboxes and rolls are received here ready to be assembled or used in repairs on the Port Talbot site. Complicated ways of working had developed over the years and no-one had ever changed these.

Within a short period 194 items were sorted out, relocated, tagged or scrapped, to the value of £30,000. CI work at Port Talbot has now yielded benefits to the value of £350,000. The new system of palletising spare parts, scheduled by a planner and then removed by forklift for storage in colour-coded bays has also provided big benefits. Orders can be cross-referenced to the pallet and fitters can find what they are looking for easily.

Many were sceptical about the CI approach but not anymore. The site is easier and safer to work in following the clean-up which visually changed the environment from being dark and dingy to bright and clean. The hardest part was changing everyone’s mind initially.

At Corus Tubes in Hartlepool, CI has led to a significant improvement in employee motivation. The plant underwent a major tidy up, with unused tools and paint being put away and equipment tagged and stored correctly. The problems were due to bad housekeeping in the main.

However, the biggest challenge was the residue given off by the processes. It gets everywhere. Steam cleaning and a lot of elbow grease on all the machinery and floors was very hard work, but following painting and whitewashing, it produced positive results for all to see. Employees were proud of what they had achieved and now enjoy a more pleasant environment to work in.

Conclusion

CI is an organisation-wide process. It seeks to always build small changes into work practice. These result from everyone in the company being keen to develop their ideas and skills, enabling step-by-step improvement.

Corus today, is a learning organisation. Key progress is seen in the growth of CI coaches and the creation of a ‘virtual’ Corus Academy. As a result, best practice can be shared right across the global Corus company. Best practice can then become standardised, so that the best developments in the UK can be applied in the Netherlands, Canada, Belgium etc, and vice versa.

The CI programme will evolve by providing customers with better value, in a cost-effective way. Putting customer needs at the heart of the business creates the Continuous Improvement culture at Corus.