Corus is part of the Tata Steel Group, the world’s sixth largest steel producer. Within Europe, Corus is the second largest steel producer with average annual revenuesof around £12 billion. The company produces more than 20 million tonnes of steel each year, mainly in the UK and the Netherlands. It has a global network of sales offices and service centres, employing around 42,000 people worldwide. Corus is a leading supplier of steel to some of the most demanding markets around the world.

Corus Long Products Business (CLPB), a business unit of Corus, has steel manufacturing facilities in England, Scotland and France. These produce different steel products from steel plate to steel rails and wire rod. The key markets for CLPB products include construction (for buildings), engineering and machinery, mining and earthmoving equipment, shipbuilding, fastenings and rail. The principal manufacturing site in Scunthorpe covers 2,000 acres and employs 4,000 people. The site consumes 6.5 million tonnes of iron ore and 2 million tonnes of coal each year to produce 4.3 million tonnes of steel products.

This case study focuses on how Corus used its knowledge and experience of continuous improvement (CI) to win new business. Continuous improvement is a tool that gives competitive advantage. This means the business can move ahead of competitors and increase its market share. Using skills and expertise in a structured way enables an organisation to create better processes and products. Corus used CI to support its new product development (NPD), enabling it to meet the needs of its customers more closely. Developing innovative products through continuous improvement is at the heart of Corus’ business strategy.

Continuous improvement enabled Corus to overcome problems in its steel works. Several years ago Corus bid for a Royal Navy contract for steel for T45 destroyer vessels. Up until that date, this was the largest Royal Navy contract awarded. Corus did not get the work because the business at that time was not seen to have the capability of meeting the high specification of steel plate required. Losing the contract showed Corus it needed to invest to improve its machinery and processes. It invested around £8 million at the Scunthorpe plate mill in order to be ready to meet the requirements of any similar contracts in the future.

The investment, together with its established Continuous Improvement practices, has enabled Corus to win a recent contract to supply steel for two new Royal Navy aircraft carriers. The £3.8 billion carriers, HMS Queen Elizabeth and HMS Prince of Wales, will enter service in 2014 and 2016 respectively. Corus will supply more than 80,000 tonnes of structural steel for the carriers. They will be the biggest and most powerful surface warships ever built for the Royal Navy.

Continuous improvement (Kaizen)

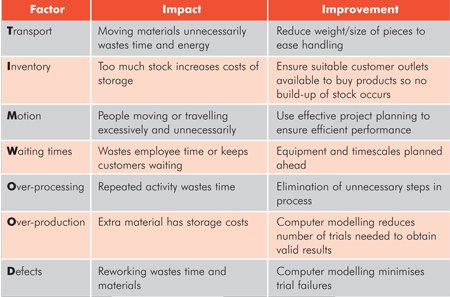

Since the 1950s many manufacturing techniques based on quality have been developed. ‘Kaizen’ is one of these and is Japanese for ‘continuous improvement’. This focuses on making small continuous improvements across all functions, systems and processes within a business. For example, waste is a cost to Corus. Continuous improvement contributes towards lean production.

Lean production occurs where:

- waste has been minimised

- the flow of work is smooth

- the business is focused on customer needs.

Lean production uses fewer resources more efficiently. This increases productivity and can improve profitability. Continuous improvement at Corus helps to eliminate waste in seven key areas. It uses the mnemonic ‘TIM WOOD’ to help employees remember the areas.

One aspect of lean production that helps to save costs of stock is the just-in-time (JIT) principle. Just-in-time means producing and supplying goods at the time they are needed. The business holds the minimum amount of raw materials and just enough finished product to meet demand. It requires well-organised systems to ensure supplies arrive and goods reach customers on time. This reduces costs and so helps to improve the return on investment for shareholders. JIT also carries risks if the business has no stock it could be less able to cope if suppliers fail to deliver. Corus needs to balance these risks against the proven benefits.

Continuous improvement influences the whole of the business. To be effective, all employees need to own and adopt CI principles, starting with senior management commitment. Under their leadership, CI works through the whole organisation. Strong communication is important in building this commitment. Corus carries out regular presentations to staff on how CI is improving the business. It also uses written forms of communication with articles in team briefings and newsletters.

Everyone has a part to play in continuous improvement. Through various CI groups, all Corus employees can contribute ideas for improving their working practices. The person doing a job often knows best how to make improvements. This empowerment of employees and managers helps them to feel valued and gives them job satisfaction.

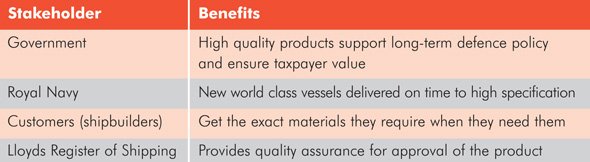

Corus benefits from becoming a more profitable business by reducing costs, securing high value orders and maximising the time its rolling mill operations are in use. Corus Research & Development benefits from the business” commitment to improvement by developing expertise and knowledge. This will support future business. Continuous improvement not only makes Corus more efficient but also provides many benefits to its external stakeholders.

Product development

The steel for the new aircraft carriers needed to meet a very high specification. Materials for warships have to be able to endure the unique conditions in which they operate, such as extreme temperatures or high seas. This contract required grades of steel with strength and toughness higher than those Corus had put forward for its previous contract bid. This represented a new product opportunity.

Product development ideas may come from:

- competitors – developing a product in response to competitors helps the industry as a whole to move forward

- changes in technologies – arising out of research and development

- innovation – using new ideas to make new products

- employees – who see opportunities from working with products

- the market – where customer demand suggests new products.

In this case, the customer, the Royal Navy, drove demand. It wanted a single preferred supplier for all the materials it needed. Corus satisfied the contract through research and innovation based on its continuous improvement processes.

During the bidding process, Corus worked with the Aircraft Carrier Design Team. This is known as ‘early vendor involvement’. Corus did this to make sure that it understood, could direct and could meet the final product specification requirements. It is a high-risk strategy as Corus had to invest money, time and effort before knowing if its bid was successful. However, this process gave Corus the time to develop the steels which had the increased levels of strength combined with toughness that the design team desired.

To add to the challenge, the Royal Navy changed the product specification during the period of the bidding process, creating new factors for Corus to overcome:

- Design requirements changed to make the ships lighter and improve speed. To save on weight, the steel plate needed to be higher strength but thinner.

- The maximum thickness of certain critical parts increased by over 40%. As the thickness of steel increases, its ability to meet the required high strength and resistance to fracture becomes increasingly more difficult.

This meant Corus had to develop a completely new product to meet this much higher specification if it was to win the contract.

Although continuous improvement usually focuses on small increases, Corus’ established systems and quality procedures helped it to meet this step change:

- Its Research & Development expertise and knowledge came up with the new steel formula that had the required toughness and strength.

- Lean production principles helped to minimise waste.

- Just in time procedures helped to meet tight deadlines.

Product testing

Steelmaking is a large-scale manufacturing process. Manufacturing involves taking all of the raw materials involved in making steel and turning them into tangible outputs. Producing large quantities reduces the cost of each piece. This is known as ‘economies of scale’.

In order to test the new steel formula properly during development, Corus needed to find a way of making small batches for testing. Corus also needed to evaluate how, if it won the bid, it would produce the steel on a large scale. Product testing is an important part of development. The small batches enabled Corus to create prototypes to test and discover how well each met the required specification.

It needed to examine which elements of the steel manufacturing process affected the strength and toughness of the plate. It was important to test various factors to see what impact changes in each would make to the finished product:

- the steel chemistry – what ingredients made the steel ‘recipe’ better?

- the reheating conditions – how did the temperature affect the steel?

- the rolling schedule – did different mill processes have an effect?

- the cooling speed – did the speed of cooling affect the product?

- the additional heat treatment processes – would additional heating change its qualities?

The product testing stage enabled Corus to make sure the final product met the required brief from the design team. It used computer modelling software to identify the impact of changes in each factor. By understanding the best combination, Corus came up with the winning formula.

Outcomes

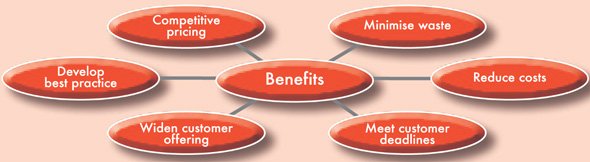

Corus developed the new steel product to help it win the Royal Navy contract. As a result, it benefited in many ways as a side effect of the changes:

- By using its existing CI procedures to guide its research and development and testing, Corus developed the new specification of steel required at a competitive price.

- Investment in new technologies and equipment, used alongside lean production techniques, enabled Corus to minimise levels of waste and reduce high manufacturing costs.

- It was able to meet customer deadlines, a vital element of making a business’ operations more competitive.

The steelmaking industry also benefited. Corus adopts a practice of benchmarking as part of its continuous improvement. It shares its best practice across the industry. Other steel businesses can now use the best methods of production to raise quality across the whole sector.

Quality assurance is a vital requirement of continuous improvement, especially in the shipbuilding industry. Steel products for this industry require approval by shipping classification societies, such as Lloyds Register of Shipping. This independent body carries out its own assessment of the test programme to ensure that materials meet full requirements for the shipping industry. Without this approval, Corus would be unable to use its materials for this type of job.

By meeting the higher specification, Corus gained Lloyds Register approval for the new steel plate it developed for the Royal Navy. This approval means that Corus can offer these high quality steels to other customers. This expands its customer base. Its investment in CI systems, research and development and the use of its employees’ knowledge have provided Corus with a distinct competitive advantage

Conclusion

In a competitive industry, businesses need to use all the resources they have, including skills and knowledge. Continuous improvement at Corus provides a process in which everybody can play a part in moving the business forward. Working in teams enables employees to share their ideas and expertise.

Using the expertise of staff helps the business to develop. It also empowers individuals to take on responsibility and provides them with increased job satisfaction.

New product development may involve risk, such as investing time, resources and money in new technologies. However, it also creates business opportunities. Continuous improvement has helped Corus to meet the Royal Navy’s increasingly sophisticated requirements for high specification steel products.

However, in meeting these needs, it has also opened up other business opportunities. By winning this contract, Corus is now able to make this higher grade steel available as part of its product portfolio. As a long-term strategy, it will help the business to outperform its competitors and increase its market share.