It is easy to take for granted everyday fast-moving consumer goods (FMCG) such as bread. When consumers go to a corner shop or the supermarket, they simply expect these products to be there and to be freshly baked. An average family will probably replace their supplies of bread several times a week.

Behind these consumer needs for fresh products, there is a complex process of production. In the case of bread, meeting these needs is not just dependent upon a bread manufacturer. The process starts with the farming of wheat. This is then milled into flour before being baked into the bread, packaged and distributed to stores to be made available to the consumer.

This case study focuses on the second largest grocery brand in the UK – Warburtons. The company is also the largest wrapped bread brand in the country, with a market share of 25.2%.

With a headquarters in Bolton, Lancashire, Warburtons employs approximately 5,000 people in 14 bakeries and 15 distribution depots. Over 800 of these workers have been with the business for more than 15 years. Every day more than two million bakery products are made and distributed around the country. This ensures that many thousands of retail outlets have freshly baked products daily.

Warburtons is a family business with family values. The fifth generation of the family is dedicated to the tradition of baking, which goes back more than 130 years.

Long term planning

Warburton’s leading position in the market is underpinned by the company’s dedication to supplying continuously high quality bakery products, whilst investing in innovation and new product development. Every organisation has to plan for the future.

The key areas of Warburton’s long-term plan are to:

- focus on quality by baking the best quality bread every day

- drive sales

- run efficient bakeries

- manage costs

- invest in people working within the business.

To do this Warburtons has taken a sustainable approach to running the business. This means that Warburtons adopts practices that can continue long into the future by managing the supply chain to meet customer needs. This involves such things as using sources that minimise the impact on the environment for future generations.

However, for Warburtons, it also includes developing long-term relationships with its stakeholders to ensure the supply of quality products for the foreseeable future.

Sectors of industry

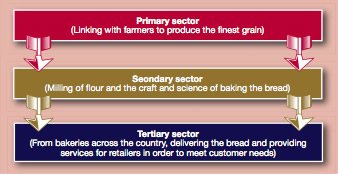

The first sector of the industry is the primary sector. This is concerned with natural resources and the extraction of raw materials. For Warburtons, this means working with farmers who grow the grain that is required to make its bread and bakery products.

The next sector of the industry is the secondary sector. This involves the manufacture or refining of goods from the raw materials obtained in the primary sector. The millers who turn the grain into flour belong to this sector, as do activities of the Warburtons organisation as it uses science and technology to create the products consumers want.

The third sector is called the tertiary sector and this is where services are provided to businesses and consumers. The distribution of Warburtons products falls into this sector, as do the services provided to retailers by the organisation.

Chain of production and added value

The chain of production sees a product move through the three sectors of industry. There are a number of different stages in the chain of production. The system starts with raw materials and may involve one or more manufacturing processes. It then finishes with final products that are ready for consumers.

During each of the different stages, value is added to the product. Value is added in a number of ways, for example:

- converting wheat into finished baked goods

- packaging them in a way that keeps them fresh

- delivering them to places that are convenient for the consumers to purchase from

- using sustainable methods and materials

- having the trusted Warburtons premium brand name.

Value added is the difference between the cost of inputs which go into making the product and the price that consumers are willing to pay.

The many sequences that link each of the different stages in the chain of production are all part of the overall supply chain. Through each of the stages in the supply chain organisations like Warburtons work hard to be distinctive and add value.

Emphasis on service

In the 19th century, the economy in the UK was mainly dependent on the primary sector. This changed in the 20th century as manufacturing grew in importance. Hence the secondary sector became the largest contributor to the economy. In the last few decades, the tertiary sector has taken over. Now approximately 75% of the UK”s GDP comes from service industries.

Although Warburton’s core activities fit in the secondary sector, more emphasis has been placed on adding value through services. The customers of bread products, and retailers, want efficient and reliable services from their suppliers. This helps them to meet the needs of their consumers more precisely.

Primary sector

Primary industries deal with natural resources. They include farming, fishing and mining. Although Warburtons does not own farms or actively farm itself, the company works very closely with farmers in the UK and Canada.

The basis of Warburton’s sustainable supply chain is to provide ‘quality without compromise’. It feels it has a responsibility to continue to deliver fresh, great tasting and high quality products. As its products depend on using the best ingredients, a close involvement with its farmers is essential. Every year Warburtons uses more than 400,000 tons of wheat. This is equivalent to 14,000 lorry loads.

By working with farmers, Warburtons can specify the types and varieties of wheat that are grown. This helps to ensure that the quality of bread is maintained. It also helps Warburtons to bake bread that is consistent in taste, softness and freshness.

Building sustainable business

More than 95% of wheat for Warburtons comes from established sources. Working with farmers helps to create the best varieties for Warburtons bread. It also means that Warburtons can work with farmers to develop more sustainable practices, particularly through the reduced use of fertilisers. In its aim to develop long-term sustainable relationships with its farmers, Warburtons prefers to pay a little more for its wheat to ensure high quality consistent supply of materials.

By working closely with suppliers, Warburtons ensures that the standards of these businesses closely match its own. For example, it expects them to be fair, decent, honest and open. The organisation has a set of ethical principles. These explain its expectations of the suppliers in terms of ethical standards in employment, working practices and environmental awareness.

Secondary sector

The secondary sector involves manufacturing products and turning them into part-finished or finished goods.

Wheat grown for Warburtons is kept separate from other wheat and cereals so supply can be traced back to the farms. It is also milled separately by flour millers, some of whom have supplied flour for Warburtons for more than 50 years. They turn grain into a part-finished good flour the basic ingredient for bread.

Throughout the manufacturing process, sustainability and efficiency are important principles. For example, wheat is shipped to the ports closest to the mills. The mills in turn produce flour for their closest bakeries. This reduces transport costs and helps to create a responsible supply chain.

Focus on quality

A focus on quality is at the heart of improving bread. Baking bread is both a craft and a science. Using technologies for mixing and kneading the dough helps to make it more elastic to create the perfect loaf. Bread needs to arrive with consumers in perfect condition. The appearance and quality of the packaging are important. This helps to create the standards that shoppers expect. Quality targets are set to ensure that bakeries bake the best bread every time.

Manufacturing is a balancing act. On the one hand, Warburton’s bakeries and departments have to manage their costs. This involves making high quality bread, whilst providing value for its customers. It involves being efficient, reducing waste and keeping health and safety risks down. On the other hand, improved efficiency should not be an excuse for poor quality. Warburtons maintains the values associated with its premium brand whilst maintaining a responsible supply chain.

New technology

A manufacturing organisation has constantly to move forward. Warburtons continually invests in plants, people and products and is also dedicated to producing new products that meet ever-changing consumer demand. It is aware of new technologies as they become available.

This means it can take advantage of new ways of producing better products. For example, in an attempt to improve energy efficiency, the organisation has put in place increased oven insulation and gas burners that shut down automatically when production stops. In addition to this, Warburtons is investigating the use of alternative and renewable sources of energy.

Tertiary sector

The tertiary sector involves providing a range of services throughout the supply chain. Although the services themselves are not physical goods, they provide added value for customers linked with the products that they buy. For example, consumers expect a range of fresh bread products to be delivered to retailers daily.

From its 14 bakeries and 15 depots around the country, Warburtons is able to meet this expectation. Warburtons has more than 900 delivery vehicles at its various bakeries. It manages the distribution to stores from bakeries across England, Scotland and Wales. This ensures that products are delivered on time. It also means that the products are fresh when they are delivered and that quality is guaranteed.

Managing environmental impact

To reduce its carbon footprint, Warburtons uses software to track delivery routes to ensure that they are as efficient as possible. It also makes deliveries at different times of the day to avoid much of the congestion on the road and save a substantial amount of fuel.

Supporting retailers

Warburton’s customers are retailers. These may be large supermarkets or small local independent shops. Retailers will often require specialist advice on how best to service the needs of their customers.

As part of its support for the tertiary sector retailers, Warburtons, for example, provides them with market research data purchased from market research agencies. This data informs retailers of selling trends and buying habits. This enables them to predict the week-by-week stock levels they require. It also helps them to allocate appropriate shelf space for products.

Warburtons also provides retailers with a wide variety of products including loaves, rolls and crumpets. This enables them to offer consumers greater choices and meet their demands for different eating occasions, such as for snacks, breakfast and lunch.

Conclusion

Warburtons have come a long way since the 1870s. The key has been the commitment that the business has made to high-quality products.

A bakery is not just about baking. For Warburtons, managing its business involves taking responsibility for managing the whole supply chain. It does this by working with farmers and supporting them as they plant the seeds on farms within the UK and Canada. It also works with millers.

Finally, it provides distinct professional services that help retailers to run their businesses more efficiently. The end result is the satisfaction felt by consumers as they finish the last crumbs on their plates.