Businesses hold stocks in a variety of forms:

- raw materials

- work-in-progress

- finished goods

- consumables

- plant and machinery spares.

The aim of stock control is to make sure that a business always has sufficient stocks to meet its own needs and those of consumers. However, it needs to keep the minimum amount of stock that it can so as to avoid damage and waste and to minimise the cost of holding stock.

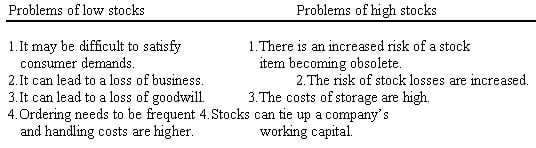

Having too high or too low a stock is harmful. High stocks represent money lying idle when it could be put to better use, whereas low stocks could result in not being able to take on and meet orders. The table illustrates the disadvantages of having the ‘wrong’ stock levels:

Buffer stocks can be built up as a preventative measure against running out of stocks due to unexpected variations in demand. A minimum level will be set, below which it will be hoped that stocks will not fall though this may depend upon the lead-time between placing an order and its receipt.

The diagram below shows an ideal situation in which stock never falls below the set minimum stock level or goes above the set maximum stock level. Stocks will be replenished just at the point at which the minimum stock level is about to be breached.

Stock Levels

Maximum stock: The most stock that the firm is willing or able to hold.

Minimum stock: This is the stock below which it is felt to be unsafe for the firm to operate.

Re-order level: The point at which the firm will re-order stock.

Re-order quantity: This is the number of new items that will be bought when stocks fall to the re-order level.