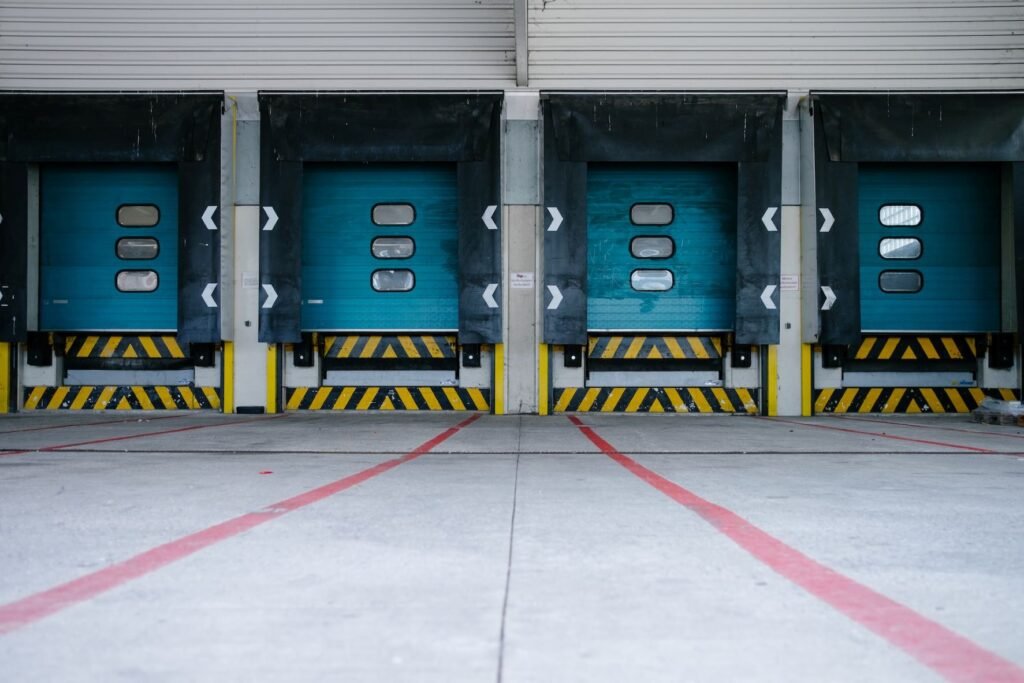

Regular preventative maintenance is an essential part of keeping loading dock equipment in top condition. Without it, the lifespan of these machines can be drastically reduced and costly repairs will be required more frequently. Here are just a few reasons why preventative maintenance is a must for loading dock equipment, courtesy of Transdek.

What is preventive maintenance?

Firstly, you may be wondering what preventative maintenance means. Typically the term maintenance means to make fixes to something that has broken. But, preventative maintenance refers to the act of regularly carrying out scheduled maintenance and servicing in order to prevent machine failures in the future.

These acts may include making small updates and repairs to areas of the machine that are essential for providing a smooth operation. Although you may not have noticed any errors or faults while running your machine, annual preventative maintenance will help to spot small problems and fix these before they become a greater issue.

Why your loading dock equipment requires regular maintenance

In terms of your loading dock and the equipment you use in this area, preventative maintenance and servicing are something that many loading bay solution providers offer to their customers. If you have purchased some loading dock equipment, such as dock lifts, dock levellers, goods lifts and more, a quality and reliable provider will offer you a service contract. This means they will provide you with after-sales care and annual service of your equipment.

Loading dock equipment in a busy warehouse will be used every day, if not every hour. This means it is equipment that is heavily used and is susceptible to breakdowns and failures. By having an annual service contract in place with your provider, you can be assured that any small issues can be quickly addressed, preventing the major failure of important machinery.

The benefits of preventative maintenance

1. Improved Safety – The primary benefit of regular maintenance is improved safety for those operating the equipment. Even small problems can have a negative impact on the performance of loading dock equipment and lead to an increased likelihood of accidents or injuries. Regularly checking and servicing your loading dock machines will help to identify any issues before they become a problem and make sure that everyone stays safe while working.

2. Extended Lifespan – Another major benefit of preventative maintenance is that it can help to extend the lifespan of your equipment. By regularly checking and servicing any issues, you can ensure that all parts are running smoothly and efficiently, reducing the risk of them breaking down prematurely or needing costly repairs.

3. Increased Efficiency – Preventative maintenance also has the added benefit of improved efficiency. Regular servicing will identify any problems with loading dock equipment and make sure that they are fixed quickly, reducing the amount of time it takes to unload or load items from or onto vehicles. This can save valuable time as well as reduce costs associated with staffing and energy consumption.