Achieving competitive advantage is not easy, particularly in global markets. Businesses that do well in these markets need to be able to use their systems, technologies and knowledge effectively across the whole of the organisation and respond to local people, cultures and different ways of working.

One such organisation that uses its knowledge and expertise to achieve competitive advantage is IMI. IMI is a global engineering group involving many different engineering specialities. It is recognised worldwide for its innovation, expertise and global service and sells engineering solutions in over 50 countries to match customer needs.

IMI’s competitive advantage comes from combining the knowledge and skills of its people with an in-depth understanding of what its customers want and need. IMI’s strengths of expertise and innovation differentiate it in the markets it serves.

IMI operates in a B2B (business to business) environment, providing tailored products and services to companies. These include large household names such as Chevron, Shell, Volvo Trucks, General Motors, Coca-Cola and McDonalds, as well as smaller niche companies dealing in specialised equipment or building materials.

Products and services

The company has a long history of working in valve and fluid engineering technology. It uses this expertise to design and develop products to control the flow of liquids or gases for organisations in a wide range of markets. These include nuclear, oil and gas, medical devices and the food and drink industry. By providing specialised products and services, IMI adds value for customers and helps them, for example, to reduce carbon emissions or improve energy efficiency.

The business spans five areas or ‘platforms’, most of which rely on IMI’s core skills and competencies in valve and fluid engineering:

- Fluid Power – develops precision-engineered valves to control air or fluid flow in many industries. Examples of applications include ventilators and anaesthesia machines; compressed air systems for train door control; and valve solutions for controlling emissions on heavy duty trucks.

- Severe Service – develops specialised valves to control the flow of steam, gas or fluids in heavy industries such as nuclear, oil and gas, and petrochemicals. These industries require the highest levels of safety, operating in conditions of extreme pressure and temperature.

- Indoor Climate – produces valve solutions for heating and cooling systems to reduce energy consumption, for example, thermostatic valves for radiators or energy efficient heating systems for office blocks such as the Shard in London.

- Beverage Dispense – provides cooling and dispensing equipment for drinks such as carbonated soft drinks and smoothies for retailers, restaurants and hotels.

- Merchandising – develops innovative displays for shops to influence consumer buying decisions.

This case study looks at how IMI has developed its strategy of ‘Engineering Advantage’, combining its skills and knowledge, customer insight and innovation to achieve global market leadership.

Setting strategy

Strategies are the long-term plans that a business puts in place to achieve its aims and objectives. IMI’s goal is to achieve market leadership in the global niche markets it serves. A niche market is a relatively small and often highly specialised segment of a market, which has few competing companies supplying it.

There are many different strategies an organisation can choose to achieve its goals. For example, these might include developing new products, growing by acquiring other companies or reducing costs. IMI’s strategy focuses on:

- increasing business in its chosen niche markets

- accelerating growth by investing in new products and emerging markets

- maintaining high operating margins and reducing costs of manufacturing and costs within its supply chain.

Few competitors can provide the specialist knowledge and tailored fluid engineering solutions IMI offers, so it is able to command higher margins for its high quality products and services in its chosen niche markets.

The IMI ‘sweetspot’

IMI’s strategy brings together three key aspects:

- its engineering skills in fluid technology and innovation

- its market leading positions in its chosen niche markets

- its exposure to markets which are benefitting from long term structural growth trends such as climate change and urbanisation.

IMI calls the point of overlap between these three factors, the ‘sweetspot’. Where these three areas come together is known as strategic convergence. It is an area where IMI expects to achieve clear market leadership, higher profit margins, greater product differentiation, opportunities to meet global trends and to grow. Over half of IMI’s operations are positioned within the strategic ‘sweetspot’ today, with plans to increase this to over 70% over the next five years.

Strategic convergence

Strategic convergence provides IMI with a clear focus. At the ‘sweetspot’ IMI’s knowledge and skills are delivering products and services which meet long term customer needs and help to give greater product differentiation. This means offering products which do things competitor products cannot. This enables IMI to attract higher profit margins as well as gaining clear market leadership and creating barriers to entry for other competitors.

This strategy IMI defines as ‘Engineering Advantage’. By understanding the needs of its markets and customers, IMI is able to provide them with customised products and services. This creates customer loyalty and enhances competitive advantage.

Business competencies

IMI’s technical focus is on the precise and reliable control of gases and fluids. However, to retain its leadership position IMI needs its people to develop business competencies such as:

- Key Account Management (KAM) – which requires highly talented and customer-focused people to maintain the company’s in-depth insight into what its markets need.

- Project management – translating the insight offered through KAM into products and services which deliver real commercial advantage for its customers. That advantage could be unique selling features to increase market share or lower supply chain costs.

- Seizing the initiative in emerging economies – IMI invests in emerging economies – areas of the world that are rapidly growing and industrialising such as China, India, Brazil and Eastern Europe. These offer great potential for growth, so IMI needs people with strong commercial skills and local market knowledge to win new business.

IMI’s people are a key factor in helping to deliver its strategy and their skills are a core competence for the business. Engineering and technical know-how is important. However, IMI looks for people who also have an entrepreneurial spirit. This mindset helps the company to look for new and creative to add value for customers and the business.

IMI also supports ongoing development of its people in various ways in order to maintain its innovative edge. For example, the IMI Key Account Management Academy not only provides training for employees but also establishes best practice across the Group. This also helps the company to transfer knowledge from one part of the business to another.

External drivers for growth

SLEPT analysis

Businesses need to take account of and react to what is happening outside the company – the external environment. These environmental factors may be analysed through the acronym SLEPT. These stand for:

- Social factors – for example, the UK’s ageing population is affecting the availability of skills

- Legal factors – regulatory standards or legislation such as Health & Safety might lead to increased training needs

- Economic factors – the current global recession is causing downturn in demand

- Political factors – government initiatives are requiring businesses to address the issues of climate change

- Technological factors – the impact of the internet makes it easier to compare the value of products and services.

These external factors may influence how a business will achieve its strategies. By monitoring the external environment it is possible to identify whether factors represent either an opportunity or a threat to achieving its strategies. IMI has identified four clear global trends within its external environment. These trends are shaping the direction that the business is taking to achieve growth.

1. Climate change

IMI has responded to this global issue by developing products to provide cleaner energy as well as helping organisations to reduce their energy consumption.

IMI is supplying severe service valves into a number of major liquefied natural gas projects (LNG) in Australasia. The demand for LNG has been growing because gas is a much cleaner fuel to use for power generation than coal. IMI has a market-leading position in applications such as anti-surge valves. These valves have to be able to provide very precise control at very low temperatures down to minus 162°C.

2. Resource scarcity

There is a global need to manage resources such as water and energy more efficiently in order to ensure sustainability. IMI is developing a range of engineering solutions to manage the use of energy, water and waste more efficiently. IMI’s innovative engineering has also developed ways of controlling building environments.

In France IMI has developed the country’s first ‘energy positive’ building which produces more energy than it consumes. IMI’s technical skills in valve and fluid control have produced a new pressurisation and heating control system. This allows the building owner to control the temperature of each room depending upon heating requirements. This not only gives better comfort to users, but the building has been designed to reduce energy consumption by 65% compared to buildings constructed under current standards of regulation.

3. Urbanisation

The rapid urbanisation taking place around the world, particularly in emerging markets such as China, requires significant investment in mass transit infrastructure. This is to ensure that the rapidly expanding urban population have reliable transport options to enable them to travel easily around the cities and, of course, to work.

CSR Zhuzhou in China services main line electric locomotive trains. They required a new type of pantograph (the equipment which links the train to the overhead electricity cables) as their existing pantograph could only cope with speeds of up to 200km per hour. IMI’s subsidiary, Norgren, was able to create a new pantograph which could operate effectively at 400km per hour in addition to coping with temperature fluctuations from – 40°C to +80°C – without affecting performance. The new technology and design not only met the high standards of the Chinese Ministry of Rail, but also effectively utilised both standard and bespoke Norgren technology to set it apart from the competition.

4. Ageing population

IMI’s technical expertise is also used to support many different types of medical equipment. As the global population is living longer, more support is needed to keep people healthy. IMI is delivering specialised products to support this.

Shenzhen Mindray Electronic Co Ltd is a developer of medical devices for patient monitoring in China. The company needed a regulator to control the flow of inlet gas for a life support ventilator. This had to meet very strict size dimensions and performance specifications. IMI’s new regulator is 15% lighter and 20% smaller than those previously available, which makes the device more portable and convenient. The new regulator is also 60% quicker to assemble and is 10% cheaper than previous models. This has enabled Mindray to supply more ventilators across China and the world and meet the increasing need for life support systems.

Internal values

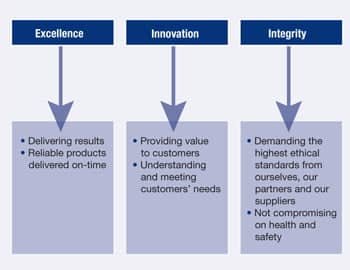

IMI believes in behaving responsibly towards all its stakeholders, including its customers, shareholders and employees. Its values of Excellence, Innovation and Integrity guide the behaviours of all employees. Values are the beliefs shared by those within an organisation which underpin its business strategies.

IMI’s values translate through its processes to increase the value of its products and services to customers. They also define the high standards for how the business and its employees deal with customers and stakeholders. This commitment to the business behaving in a responsible manner is known as the IMI Way.

The IMI Way

The IMI Way is an integrated approach across the company and enables the business to achieve sustainability in its management of:

- Health and safety – IMI promotes a strong health and safety culture. This minimises risks to people as well as to communities and the environment.

- Energy efficiency – IMI has an internal commitment to become more energy efficient in developing its products and processes.

- Risk in the supply chain – IMI sources materials and components from many countries. To make sure that products are sourced responsibly, it sets out standards for its suppliers as part of its Supply Chain policy. This includes aspects such as minimum working conditions.

- Supporting customers to act responsibly in business – IMI helps its customers to recognise and develop opportunities for sustainability.

Kroger Co. is one of the largest US grocery retailers. Sustainability is one of its core values. In 2010 it introduced a new retail service area in which frozen beverages could be served. To support this service they wanted a sustainable frozen dispenser, with high performance and reliability. IMI’s expertise produced a final product which reduced energy consumption and wear on components. In addition, the LED lighting used in the product provided seven times the life expectancy of traditional bulbs. The effect was to reduce carbon footprint, eliminate waste and create energy savings of more than 25% over traditional equipment.

Conclusion

Using a powerful combination of knowledge, skills and market insight enables IMI not only to develop innovative solutions for its customers, but also to create a competitive advantage.

IMI’s strategy of Engineering Advantage enables IMI to support its customers in niche-markets across the globe in a responsible way. It brings together the company’s values, expertise and knowledge in order to meet the challenges of the global drivers it has identified. Its strategy brings together its people and processes to maximise the capabilities of the business, provide more value for customers and make the organisation distinctive.