Business organisations prosper in proportion to their ability to add value to products. The value they create is measured in terms of consumer satisfaction. Therefore if you can find out what consumers want and need and are able to satisfy these requirements then you will have a winning formula.

This case study shows how Waitrose working in partnership with Noon Products has developed a winning formula in providing a new range of Regional Recipe Indian Meals. Today Indian Meals provide one of the fastest growing sectors of ready made meals bought by consumers. Increasingly, UK consumers are growing in sophistication and are seeking a variety of authentic top quality dishes.

With increasing disposable income, more and more families want to spoil themselves by buying up-market recipe dishes. This has provided a considerable opportunity for a quality retailer to capture the top-end of the Indian recipe dish market. Waitrose has therefore made a sound business choice by working closely with Noon Products, a company with a leading reputation in this field.

Adding value

Any business involved in adding value will require:

- Excellent links with suppliers.

- Excellent internal links between activities inside the business organisation.

- Excellent links with customers.

Links with suppliers

A business needs to make sure that it gets inputs of the right quality, at the right price and at the right time. For example, a company such as Waitrose will insist that the goods it buys from outside sources meet its own very high standards. If these standards fail to be met it will not deal with that supplier.

Internal links

In order for Waitrose to satisfy its customer needs, good links are essential for every activity within the supply chain. For example, receiving goods from the supplier, storing these goods, unpacking and displaying the goods, and selling the goods.

Links with customers

Finally, there needs to be a very close liaison with customers so that the goods can be transferred smoothly to the next stage in the chain with no hold ups or complications.

Research

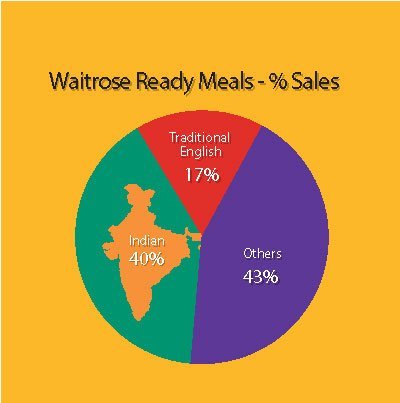

In 1995, Indian ready meals were a multi-million pound business for Waitrose and sales were increasing rapidly. Indian meals made up 40% of all Waitrose’s Own Label sales of ready meals.

Market research carried out by Waitrose indicated that the time was right for segmenting the Indian ready meal market. Consumers were looking for variety. Over the years they had become increasingly “educated” about the richness and range of Indian meals. Waitrose, therefore, wanted to further develop its partnership with Noon Products to produce a range featuring recipes from four very different regions of India.

Project brief

Waitrose, therefore, presented Noon with the following project brief.

“We would like you to develop an exclusive, up-market range of Indian dishes based on regional cuisine. A maximum of 4 regions are required, which would offer a broad spectrum of cooking styles, heat levels and types of dishes. The meals should be inventive and authentic, whilst at the same time presenting a sensible commercial proposition. Each region is to offer a complete menu in itself, i.e. a balanced range of main dishes and accompaniments.”

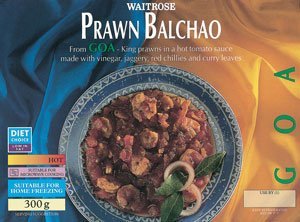

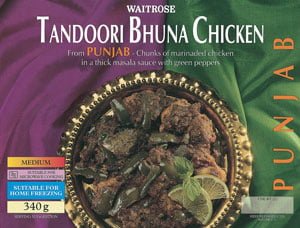

The regions that were chosen provided an exciting and innovative addition to the market. As well as including traditional British favourites such as Madras, innovative new dishes were added from Goa, the Punjab and Hyderabad. A brief glance at the four regions gives us a glimpse of the rich diversity of India.

- Goa – Goa is a small stretch of land on the west coast of India to the south of Bombay. It was ruled by the Portuguese from 1498, when Vasco de Gama landed there, up until the 1960s. Its history is therefore quite different from the rest of India and this European/Christian culture has strongly influenced the cuisine. Being a coastal area, seafood predominates and fresh coconut makes its way into most dishes. Rice is part of the staple Goan diet eaten with fiery curries made with roasted spices and vinegar.

- Punjab – Situated in the north of India Punjab is mainly agricultural; a rich fertile plain yielding wheat for bread, cane for sugar and milk for dairy products. The people of Punjab are heavy meat eaters and consumers of lentils and green leafy vegetables. The Moguls who invaded India from the north in the sixteenth century had a big influence on Punjabi cuisine. They introduced the concept of Tandoori cooking (originally a hole in the ground filled with heated stones) in which lightly marinated meats and bread were cooked.

- Madras – In Madras, which is in the south of India, it is very hot and so the food can also be very hot as it is said to cool the body. The people are mainly Hindu and the cuisine is mainly vegetarian. It is a rice producing region and this is therefore an integral part of the diet. Local herbs and spices find their way into almost every dish. The area is also famous for its coffee estates and coconut palms.

- Hyderabad – Hyderabad, in central India, was once one of the richest princely states. The area is steeped in Mogul culture and the cuisine still reflects the Mogul influence with its use of rich, exotic and expensive ingredients. Saffron and whole spices such as cardamom, cloves and cinnamon sticks are used in abundance, together with almonds, cashew nuts and yoghurt. Meat predominates over vegetables and all types of Indian breads are popular.

Suppliers

Waitrose needs to ensure that it is supplied with the Indian meals it requires, of the right quality, at the right price and at the right time. In a similar way, Noon Products needs to make sure that it gets the ingredients of the right quality at the right price and at the right time.

This highlights the international nature of the supply operations. Because Waitrose and Noon Products deal with so many suppliers, they have established highly detailed specifications for launching new products, as well as a detailed technical code of practice for suppliers.

Launching the products

A company such as Waitrose is dependent on its reputation for quality. The “quality management” process requires clear identification of customers and their needs and meeting these needs with products and services which conform with the customers’ requirements or are “fit for purpose.” It is essential therefore to build up a strong link with a supplier like Noon Products so that together the two organisations can establish and continually improve on the highest quality standards. In launching the new Indian Meals range Waitrose, therefore, required Noon to produce a Product File containing all information pertinent to the product development and launch process.

The steps which took place leading up to the launch were as follows and this pattern is typical of the way in which Waitrose operates.

- Objective -This document defined Waitrose requirements for the successful launch of the new range and highlighted the key areas of development for Noon Products. The approval sample had to be accompanied by a product file containing: Development brief; Raw materials source and specification; Audit of raw material suppliers; Test results on raw materials; Recipe formulation; Production/preparation method for presented samples; Record of production sample requirements. It was essential for Noon to demonstrate to Waitrose that raw materials and their supply are technically controlled. Noon, therefore, had to ensure that it only dealt with top quality suppliers.

- Product concept approval – Noon products submitted a range of products to the Waitrose buyer based on the development brief. Selections from that range were made and those recipes were refined over a number of weeks until the buyer was satisfied that the quality and value criteria had been met. Presentations were then made to the Head of Buying and Director of Buying for approval and to secure an agreement to commission designs.

- Factory approval – All manufacturing sites supplying Waitrose’s own label products have to be approved by the Food Technology department using the Waitrose Technical Code of Practice as the reference standard. Once approved, all sites including Noon Products, are subjected to regular surveillance visits by Waitrose Technologists.

- Product Specification/Design Brief – Following acceptance of the product range and approval of the production process, Waitrose then progressed with the design brief. Prior to the range of Indian meals going forward to the Design Meeting, Noon Products provided a complete specification including the ingredients list, nutrition information and verification of the claims they were making about their products. An analysis of the product range was carried out by an accredited independent laboratory. Clearly, at this stage, it was necessary to make some adjustments to products before they are factory tested. For example, it was decided to reduce the fat content of the Prawn Pilau and Prawn Balchao dishes so that they would qualify for Waitrose’s range of Diet Choice foods. Another example was that it was decided to use a stone grinder for grinding roasted spices – a feature which was to be highlighted on the packaging of the meals.

- Factory Trials – Waitrose requires suppliers to go through a minimum of two factory trials of new products i.e. the products need to be produced in bulk in normal factory conditions. Waitrose technologists were present at one of these trials and full records were kept. This is a detailed process in which such information is recorded such as nutritional analysis, recipe formulation, tests of raw materials, identification of safety and quality control points and many other key areas. All of this information must be kept on file. Samples from these pre-production trials will also undergo full microbiological testing to determine the shelf-life of the product.

- Product HACCP (Hazard Analysis Critical Control Point) – It is essential that all food preparation in this country is carried out to the very highest quality and safety standards. For each of the products in the Indian Meal range, a product specific hazard analysis is carried out and the critical control points are agreed with the Waitrose technologist. All food safety points and critical quality points were identified.

- Final Specification – Once the production trial samples and data had been approved by Waitrose, the final specification was drawn up for each dish and sent to the Waitrose technologist. This took place several weeks before the launch. In effect, the final specification provided a very detailed insight into how the products would be made and go well beyond the traditional cook’s recipe book. For example, a specification for Green Chutney Chicken provides details of the final weight or volume of the dish, the ingredients and their suppliers, the percentage of the ingredients in each dish, the way in which the food will be processed at each stage, how it will be packed, storage instructions and all the quality assurance procedures. In terms of quality control and attention to detail, a Waitrose Indian Meal is way ahead in performance standards of any meal which could be produced in your kitchen at home.

- Design Process – A Design brief is raised for each line which contains all the information that must appear on the pack. This information is collated by a number of different specialists: Food Technologists; Home Economists; Nutritionists; Buyer. Most of this information comes from the supplier’s specifications. The brief is then transferred to a printed format. The brief is signed by the Manager, Food Legislation, (who is responsible for the accuracy of all on-pack information), the Head of Buying and finally the Director of Buying who authorises the Design Process. A designer is chosen and briefed verbally about the products and the design objectives. At the following Design Meeting, the designer presents ‘roughs’ of a number of concepts and a decision is made about the best approach. The designer produces actual designs for the next meeting and, following approval, arranges photography of all the products and produces the artwork for each design.

- Packaging – The Artwork is examined very carefully by both Waitrose and the supplier to ensure complete accuracy. Proofs are then produced by the printer which are again checked most carefully. When the buyer and designer are satisfied that the proofs are completely accurate and have met the design objectives, approval is given for the print run to proceed.

- Product Launch – Finally, the launch was attended by the Waitrose buyer and technologist. Samples from this production were labelled and sent to the Waitrose Distribution Depot for quality control and inspection before final release to the shops.

Conclusion

This case study highlights the importance of developing the value chain and ensuring the highest possible quality standards. It also demonstrates the way in which a market conscious organisation can lead the field by identifying the type of premium products which increasingly sophisticated consumers are requiring today. Waitrose has been able to make substantial gains in the Indian recipe dish sector by building a strong partnership with Noon Products, a company which leads the field in its expertise of Indian cuisine. By cleverly diversifying into a range of top quality dishes it has been possible to meet the requirements of a range of consumers. This has been done by ensuring the highest possible quality standards. Quality is a process which involves continuous improvement. Nowhere is this more true than in food production.