Cement was invented in England in 1824 and is a key ingredient in concrete. Every year the average family uses one tonne of cement without even knowing it. No house, school, bridge or road would be built without it.

Concrete is the second most consumed substance in the world after water. It is made from aggregate, cement and water and can be mixed on building sites or supplied ready mixed from a concrete plant. The UK’s first ready mixed concrete plant was set up by a company called Ready Mixed Concrete (RMC) in the 1930s. In 2005, CEMEX acquired RMC.

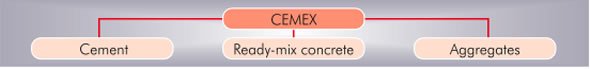

Today CEMEX is one of the world’s largest building materials companies. It is a leading supplier of aggregates (sand, gravel and crushed rock), cement and ready mixed concrete. It also produces asphalt and concrete products and has a significant share of those markets. It operates in more than 50 countries and employs over 50,000 people.

CEMEX UK has three cement plants, 60 quarries and nearly 230 readymixed concrete plants. CEMEX’s customers range from multinational building companies to individuals building their own homes. In the UK, CEMEX generates £1 billion in annual sales. CEMEX plays an essential role in contributing to creating Britain’s infrastructure, housing, schools, offices and hospitals.

This case study examines how CEMEX locates and carries out its operations in a sustainable way. Sustainable means being socially, economically and environmentally responsible to safeguard the needs of future generations.

This helps it fulfil one of its main aims – ‘to be the preferred and most efficient building materials company in the country’. It needs to ensure a good financial performance for the business. However, at the same time, it has a commitment to balancing the need for minerals against the effects of extraction and processing on both people and the environment.

Sectors of industry

There are three main sectors of industry. CEMEX’s business covers all three sectors of industry:

- Primary – involves extraction, processing and use of raw materials from the earth

- Secondary – manufacturing finished goods and construction activity

- Tertiary – providing services to businesses and consumers, e.g. retail, finance and transport.

Primary activities

In its primary activities, CEMEX extracts raw materials from the land or at sea. The process of extracting mineral deposits has to fit in with the government’s Regional Minerals Plan. This specifies how much material needs to be extracted to ensure a fair balance across the country.

Before extraction can begin, CEMEX must obtain permission from local authorities. Its plans must include sensitive ways of working, restoration and after-care of sites. This ensures the quality of the environment is maintained and improved once extraction is complete.

CEMEX’s marine aggregates business involves extracting sand and gravel from the sea bed by dredging. Dredged aggregates are vital for the future development and maintenance of our hospitals, schools, housing and transport infrastructure. They also help to replenish Britain’s beaches and protect the coastline from erosion. The UK government regulates marine dredging to minimise impact on the environment.

Secondary activities

As part of its secondary activities, CEMEX has three plants making cement. Heating clay and chalk fuses the raw materials together. The resulting materials are ground to powder as cement. The cement plants need permits from the industry regulator, the Environment Agency. CEMEX also produces ready mixed concrete, asphalt and concrete products in specialist plants. These require planning permission from local authorities and are also regulated by the Environment Agency.

Tertiary activities

In the tertiary sector, CEMEX is one of the UK’s top 20 logistics operators. It makes more than four million deliveries each year by road, rail, sea and inland waterways. CEMEX distributes raw materials and finished goods to customers for the construction of houses, schools, hospitals, bridges, offices and transport links:

- Aggregates provide the base for all types of construction products.

- Cement is sold in bulk to make ready mixed concrete and concrete products and in bags, to builders’ merchants for individuals to buy.

- Readymixed concrete and concrete products are sold to residential, commercial and public contractors.

Location of industry

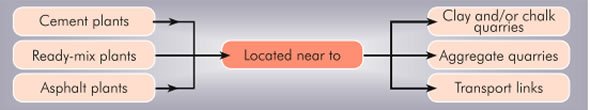

Industries usually located in places where they are close to their customers or to raw materials. This allows them to reach their market easily and to keep transport costs low. Examples include coal mines on coalfields or shipbuilding on the coast.

It is important that industries locate in the most sustainable locations. This means that industries need to find suitable locations that minimise any harmful effects on the environment. These could be where the industry produces the least amount of waste or makes minimum journeys of the finished products to distribution centres. All these factors help to protect the environment. They also give business benefits by reducing its costs and increasing its profits.

CEMEX has operational sites across the UK. It is a constant challenge to identify the most sustainable and efficient means of production across all parts of its business. This includes getting its goods to market effectively, that is, in the most sustainable and cost-effective way. Wherever possible, CEMEX locates its plants close to where the raw materials are.

National supply network

CEMEX has a national supply network in the UK with more than 400 locations. This ensures that quality building materials are available to customers locally. It aims to locate quarrying and manufacturing facilities in the most appropriate locations to meet local market needs. The majority of its ready mixed concrete and asphalt plants are sited near quarries to ensure speedy supply and to save time and travel costs.

However, large construction projects sometimes require a different approach. This was the case with the construction of the Wembley Stadium. CEMEX located its ready mix concrete plant on the construction site to improve efficiency. As the ready mixed concrete operation is automated, this required limited staff resources while still ensuring a steady supply. It also minimised environmental impact by reducing lorry journeys. A similar plant was set up for the development of a wind farm in Scotland.

Sustainable location

Quarries can only be located where minerals occur. However, the business can make decisions where to locate its secondary activity. For example, a ready mixed concrete plant could be close to its raw materials (in a quarry) or close to its markets (in a city). CEMEX’s awareness of how its choice of location has an impact on the local environment is vital to its long-term business performance.

Sustainable practices

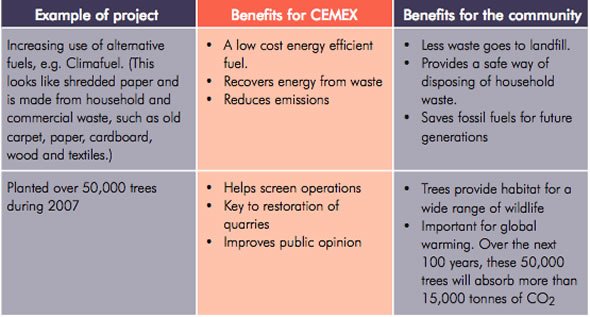

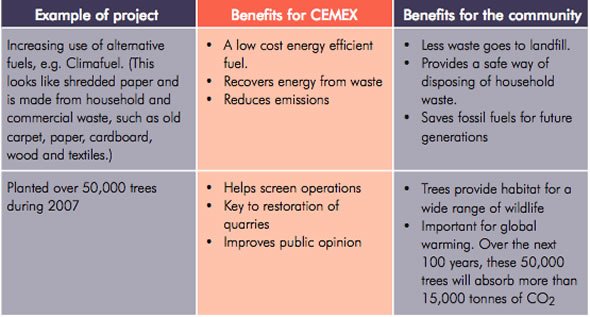

CEMEX adopts a sustainable approach wherever possible:

- It transports over 30 million tonnes a year by road, rail, river and sea, including aggregates, cement and fuel. Around 12% of total aggregates movements are made by rail. CEMEX is committed to use of rail, as these journeys give five Times fewer emissions than similar journeys by road.

- CEMEX uses water transport where possible to help minimize its carbon footprint. It transports products via sea, rivers, conveyors and underground pipelines. The longest pipeline is 57 miles long. This saves more than 400 lorry journeys per day and supports the UK Government’s objective of getting trucks off the road wherever possible. It uses barges to transport aggregates on the River Severn, where one barge can carry 350 tonnes, the equivalent of 18 HGV loads or 36 lorries.

- Making cement is energy-intensive. In 2009, CEMEX UK increased by more than 30% the use of alternative fuels such as chipped tyres and treated household waste to heat its kilns. This helped reduce emissions of CO2 across the business by 10%.

- It replaces a proportion of the cement clinker in the concrete-making process with by-products from other industries. These include slag from the steel industry and fly ash from coal fired power stations. This helps to preserve scarce minerals for future generations. Using this method reduces the carbon footprint of cement production by 50%.

Long term sustainability

As a global business, CEMEX needs to focus on financial returns to ensure long-term business sustainability, but these are not its only measures of performance. The company believes strongly all goals need to be in balance. This is set out in its position statement: ‘CEMEX is dedicated to building a better future and couples financial achievements with a firm commitment to sustainable development.’

Since entering the UK, CEMEX has invested between £30 and £60 million per annum across the business. This includes the modernisation of equipment and plants to deliver environmental improvements. For example, in 2009, CEMEX commissioned a £49 million new cement plant at Tilbury in Essex, which boasts the first vertical cement mill in the country, which uses 20-40% less energy than traditional horizontal mills.

Benefits and impacts

CEMEX has identified seven indicators to achieve a balance between its operations and the environment.

CEMEX has realised that achieving sustainable performance requires moving the company culture forward. This means it needs to change the way its people and its operations behave. Achieving change requires action in each of the seven areas.

Last year, CEMEX UK invested around £7 million in environmental improvement projects to support these seven key areas, with a focus on improving efficiency, reducing use of energy and working with communities.

Where possible, CEMEX aims to keep its business in harmony with the environment. CEMEX is careful about how it protects and restores its sites. For example:

- CEMEX Angling consists of restored sand and gravel pits. It is the largest commercial angling association in the UK. It offers over 70 mature, fish-filled lakes and 20 stretches of river.

- Eversley Quarry in Hampshire shows how the restoration of a mineral extraction site can provide benefits to the local community. Eversley now has a wide range of leisure and biodiversity developments, including a nature reserve, a golf club, playing fields and water sports. The restored quarry has won national and international recognition and major awards.

- At Barrington in Cambridgeshire, the quarry is now a geological Site of Special Scientific Interest(SSSI). A number of restored quarries have SSSI status. This does not prevent quarrying but ensures interested parties can gain access to the site. The site also contains Cambridge Greensand deposits, which are rare and rich in fossils. The SSSI status means that CEMEX must ensure that these remain exposed when the quarry is restored.

Conclusion

CEMEX provides building materials that are essential for the development, quality of life and creation of sustainable communities. Its work covers the primary, secondary and tertiary sectors of industry. It extracts and processes aggregates, produces cement, ready mix concrete, asphalt and concrete products and is involved in the distribution of its products to market.

CEMEX takes its responsibilities towards the environment seriously. It locates its business near to raw material sources or to its markets. This is cost-effective and contributes to reducing adverse impacts on the environment. Where not possible, it adopts a sustainable approach to finding alternative solutions.

CEMEX has made major investments to improve its sustainable performance. It focuses on seven key areas of activity across its operations and communities to achieve a balance between its business and the environment.