Gas is the carefully controlled source of nearly half of the country’s energy needs. And most of that gas is transported safely and reliably by a British company – Transco. All day, every day, sophisticated computer-based telemetry watches, records and reports as the gas goes through meters, compressors, valves and governors on its way to more than 20 million homes, factories and businesses. Millions of cubic metres of gas every day are pushed through the system at a steady 10-15 miles an hour.

Transco is the gas transportation arm of BG plc. The top management team comprises a managing director, chief operating officer, finance director, corporate affairs director and strategy & business development director. The business is divided into a number of groups, or directorates – licence to operate, legal, human resources, corporate projects, regulation and reform of gas trading arrangements.

Transco is highly information-rich. Its cutting edge computer systems and technological knowhow run the gas transportation network and underpin the competitive market in domestic, industrial and commercial gas supply. This case study focuses on changes to the gas industry in recent years.

Few organisations exist within a market that changes almost by the hour. Transco is able to cope with changes in demand – and this is largely because its forecasting of gas demand is accurate. It is a complicated process, taking account of all aspects of the weather and the hourly gas demands of consumers. Demand forecasts are made four times a day, but more may be made if the weather forecast or demand changes significantly.

The changing environment

Few organisations exist within a market that changes almost by the hour. Transco is able to cope with changes in demand – and this is largely because its forecasting of gas demand is accurate. It is a complicated process, taking account of all aspects of the weather and the hourly gas demands of consumers. Demand forecasts are made four times a day, but more may be made if the weather forecast or demand changes significantly.

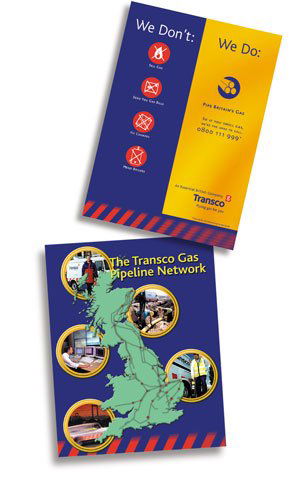

Safety and security of supply have top priority. Transco monitors the system to maintain a physical balance, making sure that gas is available at the right place at the right time. Thousands of computer simulations are run each year to ensure optimum operation of the network under all operating conditions, including planned maintenance and special operations. It’s not only ensuring security of supply that’s a crucial element of Transco’s business. Making sure that all its operations are carried out safely is vital, too. As part of Transco’s commitment to safety, it operates the national 24-hour freephone gas emergency service. Anyone who smells gas – no matter who their gas supplier is – can contact the freephone service on 0800 111 999 *.

Calls to the helpline are dealt with by trained operators at one of three national centres at Hinckley, Killingworth and Gloucester. Operators can give safety advice and, if the situation warrants it, despatch an engineer to make safe any escaping gas. An engineer has to attend within one hour if the leak is uncontrolled, two hours if controlled. It is estimated that in 1999, the service will receive around five million calls and of these, approximately half will be of an emergency nature.

Source

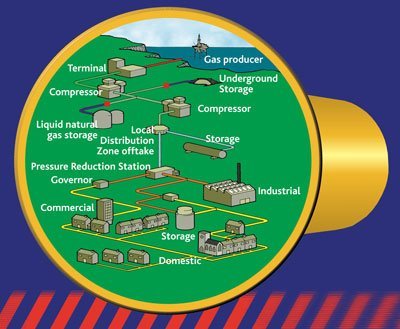

The gas starts its journey deep beneath the North Sea and is pumped ashore on the mainland of Great Britain at one of the seven terminals – St Fergus (Scotland), Bacton (Norfolk), Barrow (Cumbria), Easington (Yorkshire), Theddlethorpe (Lincolnshire), Burton Point (North Wales), and Teesside. From the terminals, it enters the National Transmission System and eventually arrives at the customer’s meter.

The Bacton-Zeebrugge interconnector links Great Britain with Europe, so during periods when the gas flows into the country rather than out, it is in theory possible that a gas consumer in Scotland could burn gas which started its journey in the Urals. Two other interconnectors supply gas from the mainland to Northern Ireland and the Irish Republic.

Nationalisation to regulation

In the past the gas industry was owned by Government, within the public sector. In 1986, gas became the first energy source in Great Britain to be regulated, three weeks after the then British Gas was privatised, with the issue of shares on the London Stock Exchange taking it into the private sector.

Even though gas is in the private sector, it is still heavily regulated. Transco is the country’s near-monopoly gas transporter and the largest of around ten public gas transporters licensed by the regulator, OFGEM (the Office of Gas and Electricity Markets) to move gas around the country. Transco’s pipeline business, because it is a monopoly, is regulated by OFGEM whose staff ensure that Transco works within the requirements of the Gas Acts and its licence conditions.

Pricing and competition

Transco’s revenues are earned within a price control linked to the rate of inflation and modified by an efficiency factor decided by the regulator who controls Transco’s revenues. The formula – RPI-X – was introduced in the mid-80s. That type of control and the regulation of profits in general was seen as a temporary means of ‘holding the fort’ until competition arrived. Developments in the price controls in both the gas and electricity supply industries – both now regulated by a common regulator – are being looked at.

Full competition in gas supply arrived in 1998, when every domestic consumer was given the opportunity to select a supplier of their choice. There is also competition in the field of gas connections and gas meter reading. OFGEM is proposing that metering will have its own price control, similar to that imposed on Transco.

From a nationalised industry to public gas transporter

1965

In the same year that The Beatles received their MBEs, the nationalised Gas Council rebuilt and modernised the UK’s gas industry. The energy map of Britain was drastically redrawn with the discovery in the North Sea of high quality gas reserves that would provide supplies for the foreseeable future. Coal and oil gasification plants become virtually obsolete.

1967-1977

In the decade that Neil Armstrong landed on the moon, the Gas Council carried out one of the biggest civil and commercial engineering programmes ever undertaken. A ten-year, £1 billion programme converted every gas appliance in the UK to use natural gas and retired existing plants. By the end of the decade, gas usage had tripled.

1971-72

Money went metric and the UK gas industry was transformed from a local manufacturer of gas with a distribution network to a full-scale energy company with operations that extended from exploration to marketing. In 1972, a new Gas Act restructured the Gas Council and regional gas boards into the nationwide British Gas Corporation.

1979

Margaret Thatcher’s first government was elected and, in a programme to be copied around the world, it prepared to privatise national corporations.

1986

The British Gas Corporation was privatised as British Gas plc, with 17 million customers, 4.5 million shareholders, over 89,000 employees and had annual cost operating profits of £688 million. It was granted a 25 year monopoly to supply gas to customers using under 25,000 therms a year and was subject to strict pricing controls by the regulator, the Office of Gas Regulation (Ofgas).

1988

Competition began to be felt. The South Morecambe gas field, British Gas’s first major independent find, was brought into operation. It was one of the largest gas fields on the UK

Continental Shelf. The Monopolies and Mergers Commission (MMC) recommended the publication of contract price schedules, allowing competitors to undercut British Gas in the 25,000-plus therms a year business user market.

1989

Ofgas issued direction for the use of common carriage rights, using the British Gas network.

1991

Government proposed a reduction of the monopoly threshold to 2,500 therms a year. British Gas was required to separate its transportation and supply businesses, and agreed to create the conditions to allow competitors to supply 60 percent of the market by 1995.

1993

Boris Yeltsin stopped an attempted coup in Russia. The MMC recommended divestment of British Gas’s gas trading business. It proposed a totally competitive gas market by 2000-2002.

British Gas announced a major restructuring into five business divisions to be completed by March 1994. The Government demanded that competition in the domestic market be phased in from 1996-1998, well ahead of the original timetable.

1994

The Channel Tunnel was completed and Transco formally separated as a stand-alone business within BG plc.

1996

Mad cow disease (BSE) and competition in domestic gas supply in the southwest hit the headlines. The Network Code, which governs relationships between gas suppliers, shippers and Transco was published and came into force.

1997

In the UK’s largest demerger, the marketing, sales and retail activities of British Gas separated to become Centrica plc. BG plc was formed and focused on the operation of the gas pipeline (through Transco) and storage systems, gas and oil exploration, international gas transportation, distribution and power generation and energy research and technology.

1998

The domestic gas market became fully competitive. Transco spent over 500 man-years to design and build the computer systems that enable the world’s largest competitive market to function.

Controlled all the way to the door

Transco’s national control centre at Hinckley, Leicestershire, monitors and controls the flow of gas through the network, operating compressor stations and flow control valves to ensure the optimum supply of gas to Transco’s local distribution zones, power stations, and other large gas users.

Every minute of every day, 44,000 telemetered items, such as pressures and flow rates, are scanned. The centre uses the demand forecasts produced by the areas, together with nominations from power stations and other large users, to determine the country’s total gas requirements. The centre also monitors the amount of gas which shippers plan to put into the system, and takes steps, including the buying and selling of gas, to ensure that supply and demand remain in balance throughout the day.

Four area control centres – at Killingworth, Hinckley, Dorking and Gloucester – operate the local gas transportation system in their area. Gas from the National Transmission System has to be reduced in pressure several times before it reaches the consumer’s meter. To achieve this, each area control centre monitors and controls up to 600 major pressure reduction stations, as well as local storage installations, which smooth out the variation in demand throughout the day.

A matter of branding

The gas industry has undergone enormous change in recent years. The monopoly of the former British Gas has been broken. Instead of being restricted to one supplier, all gas consumers can choose from a number of companies from whom to buy their gas.

With so much change, there is understandably some confusion in the public mind as to who does what within the industry. Some people find it hard to move on from the idea of ‘the gas board’. Transco is keen for its various audiences to have a clear understanding of the role it plays in helping deliver gas across the country. With that in mind, it launched a £3.75 million nationwide advertising campaign using television, radio and the press.

The theme, ‘Transco, an essential British company, piping gas for you’, continues to be used in company advertising, along with a series of ‘We do, we don’t’ adverts which seek to emphasise that Transco pipes gas and runs the gas emergency service – but doesn’t sell gas, fit cookers, send gas bills or mend boilers. Regular surveys, carried out to track public awareness of Transco as a brand, demonstrate a steady rise.