Lafarge may not be a company name that you would quickly recognise but its products and expertise have helped to create some of the UK’s biggest infrastructure projects, including the M25 motorway, the Channel Tunnel, Canary Wharf in London and several UK power stations.

The Lafarge Group is the world’s largest supplier of building materials and has a global reputation for developing creative and innovative products, services and solutions. The company produces essential products – cement, aggregates and concrete – which are integral to society. Cement and concrete are basic materials in all walks of life – everyone relies on the country’s infrastructure such as roads, hospitals, power stations, housing and railways.

The Group employs over 68,000 people in 64 countries and Lafarge’s four Business Units in the UK (Cement, Aggregates, Readymix concrete, and Asphalt) have nearly 3,000 employees working across more than 200 sites around the country. As market leader, it holds around 40% of the UK cement market. Lafarge’s business is based on its core values. These, along with highly skilled and experienced people, provide the platform for operating safely and responsibly.

Lafarge is facing many interesting challenges. As a major extractor of raw materials in the primary sector, issues of sustainability and corporate social responsibility are of high importance. The drive for increased sustainability affects every part of Lafarge’s activities – from extraction and manufacture, to transport and delivery, to waste reduction and restoration. In recognition of its high record of achievement, Lafarge has won several major industry awards in the UK, including one from the Environment Agency for its work on recycling water.

Lafarge’s values

Managing health and safety for employees, contractors, the wider public and environment throughout these processes is vital. Lafarge believes that ‘No task is so important that anyone should get hurt doing it’ (Dyfrig James, President Lafarge UK). It has a stated goal of ‘Zero Harm’ – that is, zero accidents, incidents or job-related illness. This objective applies to employees, its supply chain and the public.

Together, the drive for increased sustainability, coupled with a continuous focus on health and safety, is generating a need for high quality recruits at both graduate and apprentice levels. They will provide the creative solutions that the business and the industry need to meet these challenges. Such recruits are needed, not just in science or engineering, but also in manufacturing and commercial parts of the business.

This case study will explore how Lafarge UK is active in all three sector of industry and how it manages the need to develop the business alongside protecting the environment and respect for local communities.

Sectors of industry and sustainable supply chains

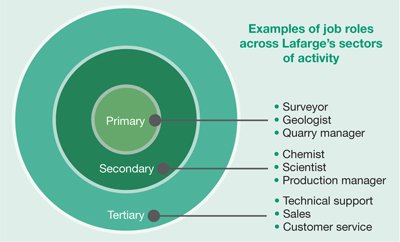

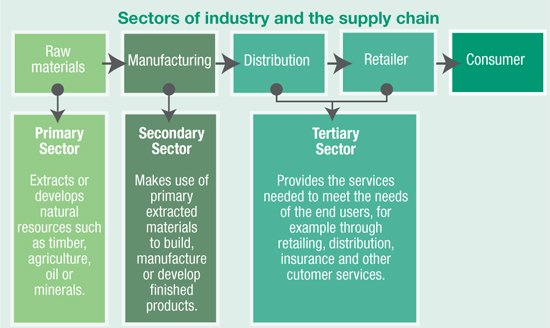

Business activities may be classified by the type of production that takes place. All activities fall into one of the following three sectors of industry:

- Primary – involving the extraction of raw materials or the growing of crops

- Secondary – involving a transformation of raw materials into finished goods

- Tertiary – covering the provision of services.

Since the C19th, the balance of UK activity overall has been changing, moving to an increasingly service-orientated economy. Industries such as mining (primary) and manufacturing (secondary) have reduced due to cheaper goods from overseas competitors. In 2011, the primary sector accounted for 1.4% of UK GDP, the secondary sector for around 22% of GDP, with the tertiary sector dominating with just over 76% of GDP. However, certain key industries in the UK, such as steel and cement, have experienced growth, with new technologies and innovation driving demand. Lafarge therefore needs more people with both specialist and generalist skills to meet that growth.

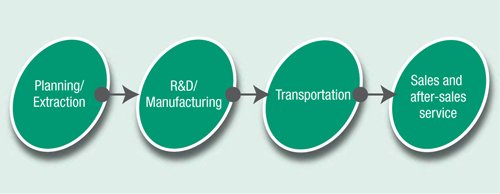

The interdependence between the sectors is known as the ‘chain of production’. This identifies the interlinked stages that a product goes through from raw materials to arriving at the final customer. Each stage adds value to the previous one. A sustainable supply chain aims to ensure that the business is conducted in a manner which can be maintained in the future and which does not impact adversely on future generations. The key challenge is to deliver products and services that give value to the business and the customer, whilst maintaining a positive environmental impact.

Lafarge operates in all three sectors of its industry, extracting raw materials, manufacturing finished goods and providing sales and after-sales service for customers. In this way, Lafarge is able to take control of and manage not just operational efficiencies but also quality, health and safety and its impact on the environment.

Primary sector

Cement is a product that originally dates back to the Egyptians and Romans. However, since its ‘rediscovery’ in the C19th, it has been evolving in response to new technology and innovation resulting in the complex product of today. In a typical year, the UK mineral products industry contributes to the building of 160,000 new homes, improvements to water services and the maintenance of the UK road and rail networks.

There are around 1,300 quarries and manufacturing sites in the UK producing £5bn worth of products each year. Over 80% of the raw materials used in its processes come from Lafarge’s own operations and are therefore under its direct control. This integrated supply chain ensures Lafarge can manage quality, quantity and guaranteed delivery though its own activities.

In its primary sector activities, Lafarge’s extraction processes involve drilling or controlled explosions to blast limestone, granite, shale or clay from quarries. This provides the raw ingredients required to make cement, aggregates and concrete. The rock is transported to a crusher to produce the different sizes of rock needed to suit different products for customers.

Sustainability

Lafarge is committed to sourcing its materials and managing extraction in the most responsible and sustainable way possible. Rock quarries are usually operated for many decades and then restored. Sand and gravel quarries are shallower than rock quarries and can be worked in stages. This means the land is used and restored in phases. As the majority of raw materials to make cement come from new quarries, Lafarge is also investigating how it can reduce dependence on these sources. It is looking at ways of treating waste and by-products from other industries to replace natural materials. This is an important aspect of its sustainable practices.

In addition, it works with external bodies such as the Environment Agency in the planning stages of assessing a new quarry site. This means Lafarge can take into account key issues affecting the environment from the outset. At the end of the quarry’s life, Lafarge is committed to the restoration of land. For example, it uses recovered inert waste from its extraction and waste management processes as part of the restoration process.

It then works in partnership with other organisations (such as the Staffordshire Wildlife Trust) to re-use the land for the good of the community and to provide a lasting legacy. For example, the National Memorial in Staffordshire is on a former quarry site. Lafarge has also been involved in managing 34 SSSIs (Sites of Special Scientific Interest), as well as creating award-winning parks, lakes and education centres. Over 700 SSSIs have been developed in the UK from former sites of mineral operations.

Secondary sector

A business will aim to add value (both financial and non-financial) as a product moves from inputs to outputs across the three sectors of industry.

Globally Lafarge invests over 170 million Euros every year into research and development. This makes it one of the world’s leading research and development companies. This investment helps to provide ongoing innovation in its secondary sector production processes which benefits customers. Its skilled chemists and scientists work in laboratories across the UK. For example, it created a self-compacting concrete called Agilia®. This saves customers’ time and money in the construction process.

It creates value for the client due to less time being needed for application and lower costs of equipment. This also contributes to a healthier environment for construction workers.

The manufacturing process to create cement involves heating the raw materials to a very high temperature, grinding the clinker finely and adding different minerals to the resulting cement to give different properties. Important properties customers look for include increased resistance to weather or a higher quality finish. Lafarge is the leader in the development of low carbon cement products and has five main manufacturing locations, producing 5 million tonnes of cement each year.

Reviewing processes

By its nature, cement manufacturing consumes large amounts of non-renewable resources and also generates CO2. Lafarge is therefore committed to reviewing its processes to reduce its impact on the environment. Its production plants are certified under British Standards for both quality and environmental management. One way in which Lafarge helps to minimise its impact and emissions is by having on-site concrete production plants for large-scale projects. This is more efficient and enables Lafarge to provide continuous supply throughout the life of the project.

As a major user of significant amounts of water in its processes, Lafarge is also piloting ‘water footprint’ assessments. These aim to use water more efficiently and reduce consumption where possible. Other examples of Lafarge’s ‘best practice’ include:

- using the fly-ash waste product from iron and steel smelting to make low-carbon cement

- using alternatives to fossil fuels (such as chipped used tyres) in the kiln heating process

- investing in more efficient manufacturing units

- offering a cement recycling service to customers for unused, outdated bags of products.

Lafarge also takes innovation right through the supply chain into its packaging. Its weather-resistant plastic packaging is easier to handle and is tear resistant. Both effects benefit customers. Plastic packaging for cement perhaps surprisingly, is more sustainable than paper as less material is lost through damaged bags, which is better for the environment.

Tertiary sector

At the later stages of the supply chain, Lafarge’s activities in the tertiary (or service) sector range from transporting finished goods to providing a specialist advice and after-sales service for customers. This ensures they get the best use of the products.

Lafarge supplies its products in large volumes to intermediaries, such as local authorities or building companies, where the products are used on major projects. An example is Terminal 5 at Heathrow Airport.

Lafarge uses different means of transport – road, rail and water – to help it reduce carbon emissions wherever possible. Lafarge has a fleet of road vehicles for transporting bulk cement. It has modernised the fleet to increase the loads each tanker can carry in order to reduce the number of vehicles on the road and reduce emissions. Of its nationwide network of 14 depots, 11 have direct rail access. More than one million tonnes of cement a year is moved by rail, more than any other company. This removes hundreds of thousands of vehicles off the roads each year, reducing congestion, pollution and CO2 emissions. Lafarge is also an expert in transporting by water.

Adding value

One important area of added value for customers is through Lafarge’s Construction Solutions and Contracting services. Its technical sales people, along with IT, purchasing and customer service teams, provide ongoing support and advice for customers.

- Lafarge Contracting specialises in providing asphalt based solutions for surfacing projects. These might be as wide ranging as car parks, race tracks, bus lanes, housing developments and airport runways.

- Construction Solutions uses all Lafarge’s expertise, from aggregates to cement, to offer a ‘one-stop-shop’ service. This provides all the expertise and materials to take a project from initial design, through production, to finished installation in one combined service.

Lafarge continues to demonstrate its innovation and sustainability in the tertiary sector. As part of its sustainability plans, Lafarge goes beyond simply managing or restoring its extraction sites. By adopting the principles of re-using waste products from other industries, Lafarge can respond to environmental challenges in a sustainable way:

- Its energy recovery service recycles used tyres for fuel.

- Landfill sites have processes for separating out waste in order to recover re-usable materials.

Conclusion

To generate the cement and concrete that the building industry needs, it is necessary to extract raw materials from the earth. In order to minimise the impact its activities have on the environment and create a sustainable business, Lafarge has put in place principles and best practices across its integrated supply chain.

By focusing on re-use, recycling and reducing emissions in every stage, from initial planning of a quarry, to final restoration of the land, Lafarge is maintaining a sound business whilst respecting the environment and supporting local communities.

Lafarge continues to be heavily involved in restoration projects such as the newly completed Chalk Grassland project in Kent which has restored 40 hectares of grassland for sheep grazing. It is also in partnership with the RSPB at a prospective project at the Dunbar Works in Scotland, where the quarry site is being transformed into a nature reserve.