Most of us love chocolate in one form or another and every week a typical UK citizen spends around £1.80 on it. Amazingly, UK consumers have a choice of over 5,000 chocolate lines available from 150,000 outlets. Because it is so widely and readily available, we tend to take chocolate for granted, and few of us probably ever consider what is involved in producing it.

This case study looks at the massive, complex worldwide operations that ensures that chocolate products are on the shelves of retail outlets 365 days a year. We tend to treat this achievement as routine. In reality, it represents a triumph for careful planning and meticulous organisation. We don’t know who first discovered that cocoa beans could be turned into a drink, but we do know that by 600AD the Mayan people living in what is now Mexico were growing cocoa in the jungles of Yucatan.

In the 16th century the Spaniards invaded South America, quickly learned the secrets of making chocolate as a drink and started shipping back cargoes of cocoa beans. By the 18th century, chocolate-based drinks were popular in British high society. In the mid-19th century an English cocoa manufacturer, Joseph Storrs Fry, tried mixing cocoa butter with sugar and cocoa paste and invented the world’s first solid blocks of chocolate.

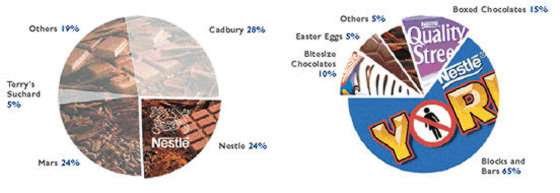

The UK has long been a major manufacturer (and consumer) of chocolate products. All over the world you will find prominent brands first developed in the UK e.g. Smarties, Dairy Milk, Aero and of course Kit Kat (the UK’s Number 1 selling confectionery brand since 1985). Three producers dominate the chocolate market. Cadbury with around 28% while Mars and Nestlé each have around 24%. Sales of milk chocolate (96%) predominate, with plain and white chocolate accounting for about 2% each. Boxed chocolates such as Quality Street make up 15% of the confectionery market. Blocks and bars like Kit Kat and Yorkie account for 65% and bitesize chocolates e.g. Smarties and Rolo make up 10%. Easter eggs are another big seller, accounting for 5% of the market.

The UK’s chocolate industry is over 150 years old. Chocolate manufacture provides steady employment and job security for tens of thousands of employees in manufacturing locations like York and Birmingham. The industry also generates jobs in marketing, administration, transport and storage. Chocolate sales are an important source of income for many retailers.

Resources needed for production

All goods and services depend on resources for their production, these are known as factors of production. One key factor is enterprise: the risk-bearing associated with any business. In the past, many firms owed their existence to perhaps just one person, who set it up. Nowadays, with the growth of companies, business risk tends to be born by shareholders, whilst managers exercise day to day control.

Manufacturing, marketing and distributing a product for worldwide consumption involves a huge amount of careful planning.

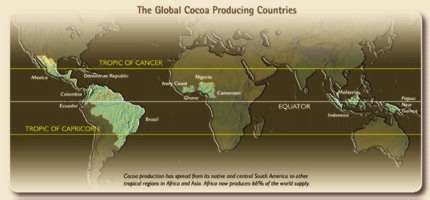

A second major resource is the land: cocoa trees grow on it, chocolate factories are built on it. Cocoa is grown in Central and South America, the west coast of Africa and more recently in South East Asia. Eight countries – Ivory Coast, Ghana, Indonesia, Nigeria, Brazil, Cameroon, Ecuador and Malaysia supply 88% of world output. Over 40% of the world’s supply comes from Ivory Coast, where cocoa is grown mainly on over 600,000 small, family-owned farms. Most cocoa farms occupy between one and three hectares.

Labour is another key input. Small farmers (who are entrepreneurs in their own right) have developed the skill of producing a high yielding, top grade product. Cocoa production is often their only source of income. They may also grow subsistence crops such as yams or palms, but they typically rely on the cash from cocoa to pay for extras such as health services and educating their children. Raw materials are another important resource within the production process. Besides the cocoa beans themselves, raw materials for the chocolate industry include sugar, milk and wrapping/packaging materials e.g. paper, foil and card. Another input is the buildings, plant and equipment required for manufacturing and distribution e.g. factory premises, complex machines and fleets of trucks. These items are known as capital.

Issues in the supply chain

As a major buyer, Nestlé seeks to be as closely involved in the supply chain as possible, to ensure quality and fairness. Currently, Neslé is participating in a process to examine potential problems of forced child labour on cocoa farms in West Africa. This is being done on an industry wide basis, in consultation with governments, labour organisations and Non-Governmental Organisations (NGO), as well as with other members of the cocoa and chocolate industry. We strictly monitor that no child labour is used in Nestlé facilities and reject industrial suppliers who do so. We hope that the constructive dialogue that has been started on this issue will continue and that these discussions will result in pragmatic approaches to doing what is best for workers in Western Africa.

Chain of production

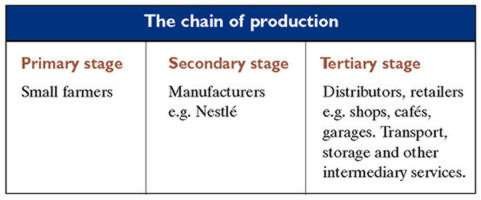

The supply chain is the sequence of activities and processes required to convert raw materials and components into consumer goods and services and to deliver them to the consumer. For cocoa, the chain is often complex and varies from one country to another. However, a typical pattern would pass through the following stages.

Primary producers

The first stage is to grow the cocoa beans. Often the many small farmers involved will live some distance from the market. They depend on people operating in the tertiary or service sector of the economy to collect, purchase and transport the cocoa product to warehouses. In an exporting country like Ivory Coast, export warehouses are located near one of the country’s ports, Abidjan and San Pedro. It is at this stage that companies such as Nestlé play an important role in the supply chain by checking consignments for quality. Nestlé may buy directly from an export warehouse, or it may approach intermediary suppliers who buy cocoa beans in bulk from across the world and arrange shipment to the confectionery manufacturers.

Secondary stage

The secondary stage of production is the manufacturing companies. These companies bring together the sugar, cocoa and other raw materials to manufacture the chocolate products we know so well: they convert the beans into chocolate bars and other finished products.

Tertiary stage

The final stage in the production chain is selling (retailing) to final consumers. Just as Nestlé buys in bulk from exporters and suppliers, retailers buy in bulk from Nestlé. Every Kit Kat or other chocolate product that you buy will have been through all these stages of production.

Production

Chocolate production consists of many stages. Farmers are at the start of the production chain.

- Cocoa plants are generally grown in low lying areas and planted in the shade of other trees such as banana or coconut. It takes up to five years for a new plant to fruit, after which it may have a life span of 30 years, unless severe weather or disease destroys it.

- Ripe pods are cut from the tree, broken open and the beans removed.

- The beans are then allowed to ferment, often in baskets, perforated vats, holes in the ground, or in piles covered by banana leaves. This process takes about six days.

- The beans will by now have turned brown. They will then be spread out to dry in the sun. Sometimes they are dried artificially. This process reduces the moisture content from 60 to 13

- The beans are then sold. Manufacturers and processors are the major buyers.

The manufacturer then takes over the production process. This involves:

- cleaning: ensuring materials such as sticks and stones are removed

- winnowing: the shells are cracked open, the beans isolated, collected and heated

- roasting: the beans are roasted in furnaces at temperatures between 100ºc and 150ºc for 20 to 50 minutes. This releases the cocoa’s full flavour and aroma

- grinding: this process breaks down the cocoa butter on the beans and produces a smooth liquid (cocoa paste)

- blending: different varieties of cocoa paste are combined to ensure a consistent final product and to determine the flavour, quality and hardness of the chocolate.

Thereafter, manufacture follows two different paths to produce either cocoa powder (used in chocolate drinks, pastries, ice creams and desserts) or solid chocolate. Because cocoa powder requires a low fat content, the paste is pressed to remove most of the cocoa butter. It is then crushed, pulverised and finely sieved. Making solid chocolate requires combinations of four basic ingredients: cocoa paste, cocoa butter, sugar and milk. The mixture depends on the type of chocolate being produced. Other processes involved in providing high quality chocolate include:

- refining to reduce the size of the particles

- conching (stirring) to produce a smooth and glossy chocolate

- tempering (heating at 45ºc to produce an even smoother end product

- moulding the chocolate into shape, before it is finally packaged.

Typically, chocolates are produced using a continuous flow method along a production line dedicated to producing large quantities of a single product. To make soft-centre items such as Rolo, liquid chocolate is poured into deep moulds. These are inverted very quickly, leaving a coating of chocolate on the inside. Once this hardens, the mould is again turned over. The filling is then poured inside and covered with another layer of chocolate to form the base. A continuous flow method is far more economical than producing in batches, for example, because once the equipment settings have been established the line can run cost efficiently. This production advantage is known as a technical economy of scale. By producing very large quantities at very low costs per unit, a company like Nestlé is able to offer consumers good value for money and so remain competitive.

Conclusion

Large confectionery companies meet customer requirements with a wide selection of different types of chocolate products to meet a variety of tastes. A company like Nestlé is involved at every stage of the production chain. It gets to know as many people as possible in the supply chain, providing growers with technical advice, advising intermediaries about quality issues, and of course researching the market to find out what the consumer wants.

Large organisations like Nestlé are able to pass on to us the benefits of economies of scale, coupled with their experience of producing high quality chocolates over many years. As a result, we consumers are able to enjoy products built around cocoa beans from a small farm and transformed by complex production processes into sophisticated products such as Quality Street, Smarties, Aero, or many other forms of chocolate product.

Nestlé | From bean to bar – the production process