In the ever-evolving world of construction, one element that has withstood all the tests of the time-bricks. Bricks have been a cornerstone of architecture for centuries, providing strength and durability to structures around the world.

Then, let us discuss the wonderful innovation that has made it possible for us to produce this foundational strength of buildings, that we call as bricks, let us discuss the brick making machine.

BRICK MAKING MACHINE

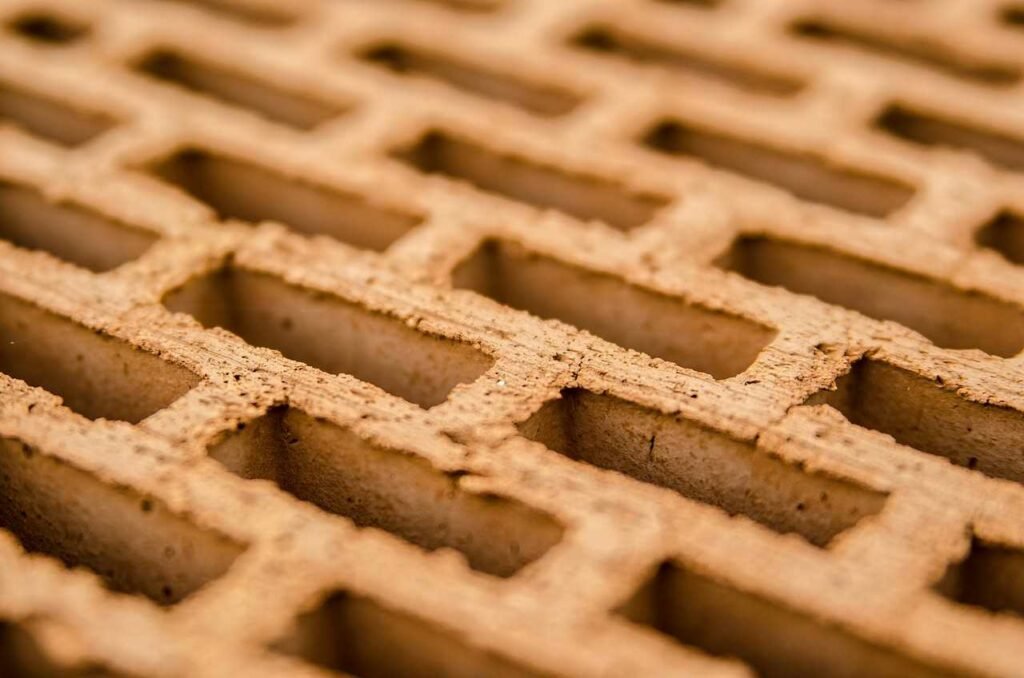

A cutting-edge innovation in the world of construction and infrastructure world. Brick making machine is a mechanical instrument built and designed to manufacture bricks. This is from various raw materials, typically clay or concrete, coal gangue, fly ash, mountain mud, slag and slit. There are different types of these machines, such as, manual, semi-automatic and fully automatic, and all of them have varied production capacities. These machines automate the process of forming, drying and firing bricks. Their work is based on moving technology.

Over the next five years, we can expect an upsurge in the technological advancements and innovations that will redefine the way bricks are made and upgrade to a more sustainable and efficient future of construction. The construction business is predictably about to bring transformative changes shortly. One of the most anticipated players in this evolution will be brick making machine.

FUTURE OF BRICK MAKING MACHINE

The future of brick making machines in next 5 years is going to be a revolutionizing period for the construction and infrastructure businesses, due to various aspects, such as

- SMART MANUFACTURING – Technologies will climb up in the era of smart manufacturing for brick-making machines. Consistent maintenance with uniformity of time, proper monitoring and data analytics will become essential to ensure optimal machine performance. Minimizing input time requirements and maximizing productive output.

- ADVANCED MATERIALS – Thorough research by the Research and Development sector in material science. This will work as a major catalyst in the evolution of brick composition by the brick-making machine. We can expect to see enhanced qualities of bricks such as improved insulation, increased durability, and smart features like sensors for temperature, etc., in the coming future.

- AUTOMATION INTEGRATION – The future of brick-making machines lies in increased automation. The future will swiftly move towards fully automated systems that along with moulding bricks, will also handle tasks such as material feeding, curing and packaging. This will boost production rates and reduce labour costs, thus, enhancing efficiency overall.

- MODULAR AND CUSTOMIZABLE DESIGNS – Brick & Concrete block making machine will most probably offer modular and customizable options, making it possible to produce bricks in preferred shapes, sizes and textures. This upgraded adaptability will enhance flexibility in brick designs, making it a focal point, and will cater to diverse architectural needs and preferred designs.

- GREEN TECHNOLOGY – Indeed, sustainability is a driving force in the construction industry. In the next 5 years, brick-making machines are likely to follow and adopt green technology. This includes the use of recycled materials in brick production, energy-efficient manufacturing processes, and the integration of eco-friendly materials. Which if combined altogether, will reduce the impact on the environment due to brick production.

- GLOBAL CONNECTIVITY – The future of brick-making machines is not limited to national boundaries, but it also rises with the rising globalization and connectivity. With all the advancements and progress in future. The manufacturers and users worldwide will be able to share insights, best practices, and innovations globally. This connectivity will foster a collaborative environment and consistent improvement.

Therefore, in conclusion, as we look ahead to the future of brick-making machines in the next five years, we can say that it will be a very promising and dynamic tomorrow. Embracing automation, sustainability, smart manufacturing, and advanced materials will redefine the construction and infrastructure industries. These innovations signify the increased efficiency and commitment to building a more substantial and technologically advanced future. The brick-making machine is destined to play a crucial role in shaping and constructing the future world.