It is easy to identify key competitors in a market by their goods or services. These products clearly meet customer needs in terms of the range of benefits they offer. However, an organisation has to develop, manage and integrate many different processes from across its business prior to launching the product into the marketplace. To achieve a competitive advantage it has to manage this process more efficiently than competitors.

The ability to survive and grow in these long-term competitive markets therefore, not only depends upon how organisations bring new and innovative products to market but also how they manage and develop all of the business processes that allow these innovative products to be supplied to their customers.

An organisation’s performance will involve business processes working together to add value to a range of inputs in order to create a series of outputs. In a factory, for example, operations would involve bringing together finance, labour, equipment, materials, administration, marketing expertise, as well as the creative and efficient use of people and management processes to transform all of these inputs into desirable goods and services which meet or exceed customers expectations.

This case study illustrates how a large global manufacturing organisation, Cummins, uses an initiative called ‘Six Sigma’ for rapid process improvement from a range of key elements across the organisation to significantly improve its business processes. Using statistical tools and data as a base for analysis and a disciplined, logical approach, Six Sigma enables decision-takers within Cummins to improve their understanding of critical business and operational processes, generating major cost savings, developing and sharing best practices.

Worldwide over 1,000 Six Sigma projects have been completed by Cummins generating almost $400 million dollars in corporate savings over just three years. At any one time there are over 500 projects being worked on and 500 projects ready to be implemented.

Those involved in leading Six Sigma projects are known as either ‘green belts’ assigned to projects part-time or ‘black belts’ who are specialists leaders working full-time. The training involves creating a new way of thinking about how to meet customer needs.

Within Cummins UK, more than 200 staff have been trained as ‘belts’ and are leading the initiative. Each project is completed in six months or less to bring a sharper focus and to ensure measurable results can be identified and sustained. Six Sigma is, therefore, more than a statistical tool. It is part of Cummins’ overall business model, developing better business processes to suit higher customer expectations.

Cummins – a global organisation

Operating in B2B markets, Cummins is a leading world-wide designer and manufacturer of high performance diesel engines, electrical power generation systems and related products – including Holset turbochargers, Newage AvK SEG alternators, Fleetguard filtration and emissions solutions. The Cummins UK organisation includes six major manufacturing facilities employing almost 5,000 people and exporting over 70of output.

In 2002 the company achieved the unique distinction of two Queens Awards for International Trade and one for Technology. Cummins diesel engines are used to power everything from trucks, buses, construction equipment, tractors and boats, to trains and huge mining excavators. Cummins Power Generation provides generator sets for emergency standby power, combined heat and power installations (CHP) using natural gas, and complete power plants.

With headquarters in Columbus, Indiana (USA), Cummins strength lies as a diversified company that leads many different global markets for engineered products.

In global markets customers should be treated as equally important, whatever their distance from a head office. It has been argued that organisations must establish a presence in all major trading areas of the world, or risk being overtaken by those who do. This is particularly the case for manufacturing markets in which Cummins operates. Competition in these markets is global, customers can choose products and services from many different sources.

Cummins aims to put its customers first and provide real value by using innovative technology and processes to develop its products better than its competitors. A key element in being able to do so has been Six Sigma. Six Sigma is used as a mechanism to aid process improvement thereby exceeding customers’ quality expectations and producing the opportunity for future profitable growth.

Cummins Operating System business model

The focus for any business model is a vision that shows a clear idea of where an organisation is going. The company’s vision is ‘making people’s lives better by unleashing the Power of Cummins’. This vision is then translated into objectives such as:

- motivating people to act like owners working together

- exceeding customer expectations by always being first to market with the best products

- partnering with customers to make sure that they succeed

- demanding that everything Cummins does leads to a cleaner, healthier and safer environment

- creating wealth for all stakeholders.

Achieving this vision is based on a single business operating system known as COS – Cummins Operating System, utilised throughout the company. This incorporates 10 major practices, as illustrated, with Six Sigma as the primary process improvement method. COS practices understand the requirements of both internal and external customers. Having understood these requirements Cummins can then compare its desired and current performance.

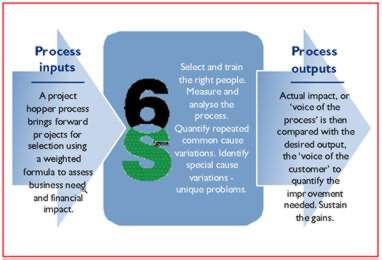

Six Sigma is not simply a quality initiative and nor is it just about solving problems. It is about making major process improvements in key areas of the business where a gap exists between desired and current levels of performance. This starting point provides an opportunity for Cummins to look carefully at every input into its business processes.

Six Sigma therefore helps Cummins to understand the key processes in helping it to deliver results; and provides an appreciation that the business outputs are determined by the processes that the inputs go through to become outputs. Using Six Sigma to improve business processes for selected projects thus enables positive gains to be made in key areas of the business.

The role of data

There is a range of data that provides the raw information about business processes. Data, for example, might illustrate how a process is running, include accounting information, technical process data and customer information. This performance data can be entered into spreadsheets, although this data might help to provide a better understanding of the business, it does not always contribute to making business decisions.

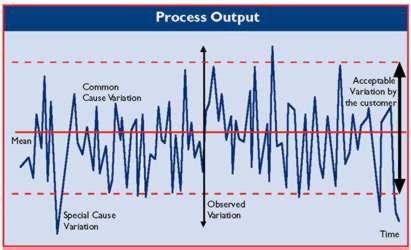

Six Sigma involves converting data to information and then creating statistical images of the process. These pictures help to show how results vary within processes and provide a basis for understanding this variability. It is then possible to identify the gap between the ability of the process and the level of performance desired by the customer.

At its very basic level, when put together, data can be used to illustrate average or mean levels of performance. For example, on average it may take 30 days for a company to meet a particular customer need. However sometimes that need might be met in 20 days, while at other times it might take 40 days. In order to improve the process, it is important to understand the causes of this variation. By understanding the critical inputs that cause the variation it may be possible to reduce this variation to align with customers’ needs.

By listening to the voice of the customer, and then using data to quantify the variation, work can take place upon identifying the critical elements causing the variation. This leads to improved business processes and therefore increased customer satisfaction.

Improvement methodology

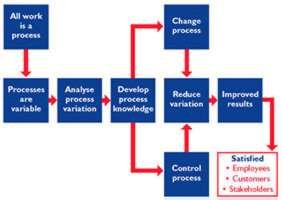

Quality is therefore customer driven, with a link between customer expectations and the processes that provide the results that customers require. Cummins has therefore moved from a results orientation to a balanced results and process-driven method of working, focused upon the customer.

The starting point for Six Sigma is to understand the critical inputs that determine the quality of output. Once processes have been developed to understand these inputs and their levels of predictability, managers are then in control of process variation. Six Sigma involves setting up projects that focus upon identifying and controlling these critical inputs, so that processes and outputs can be improved and sustained.

Six Sigma is therefore not about improving the technology. It is more about developing a cultural change within the organisation, influencing how Cummins and its staff think and work. It is about increasing the emphasis on process and process capability. This requires training, understanding, motivation, recognition and leadership.

The methodology involves statistical analysis to quantify repeated Common Cause Variation which can then be reduced by the Six Sigma improvement team. This also identifies Special Cause Variations characterised as unique, assignable problems, handled by problem solving techniques.

Conclusion

Six Sigma looks at all work as a series of processes with inherent variations, which can cause waste or inefficiency. Focusing on those processes with greatest impact on business performance, as defined by leadership teams, the methodology involves statistical analysis to quantify repeated common cause variations – which can then be reduced by the Six Sigma team. Six Sigma becomes a continuous process for quality improvement and cost reduction flowing throughout the company.

Originally developed from a Japanese quality control process for manufacturing electronic semi-conductors, Six Sigma developed the capability of reducing problems or issues effecting customer expectations on key business processes. Six Sigma has provided the opportunity to drive forward important customer focused initiatives across the Cummins global organisation.

As an improvement and cost reduction process, Six Sigma is equally valid for marketing and product development as well as manufacturing and customer services. Six Sigma improvement projects and techniques are now the cornerstone of Cummins continued success in cost reduction and quality improvement.

Cummins | Using Six Sigma statistical thinking to improve business processes