Do you ever think about what goes into a motor car, a power tool or a particular type of domestic appliance? If you were asked this question you would probably look for the technical features of each of the products, against which you can associate some form of tangible benefit, such as fuel-injection systems, ABS, a hammer drill, airbags, the time it takes for a kettle to heat up or the cool-wall in your toaster.

These technologies are all – to a certain extent – visible, known to us as products or identifiable with companies and what they do. What we don’t tend to see or even think about are the materials and components behind such technologies. Complex manufactured products are made up of numerous parts. For such products to operate in a way which provide the benefits we demand as consumers, the various components within the products must operate according to high specifications, which largely depend upon the materials used in their manufacture.

If we mentioned the name Land Rover, you would instantly recognise it. This is because Land Rover is a product largely targeted at consumer markets in which you operate as a buyer or user. In fact, the product publicises itself every time one is driven past you. Unlike the Land Rover, the name Morgan Crucible is not so recognisable because instead of operating in consumer markets, it operates within industrial markets, developing products for organisations rather than for individuals.

These are markets where organisations buy products which are either directly or indirectly used in the production of other goods. But this does not mean to say that consumers are not benefiting from such products, since these products provide the components and technology behind many of the things we frequently use, even vehicles like Land Rover. We just don’t realise how or when! This case study focuses upon the strategic operations of Morgan Crucible, a business which specialises in being able to develop, manufacture and market materials technology into new or existing products, used day-today by consumers and organisations across the globe.

Morgan Crucible Company plc is a UK-based international group which manufactures specialised materials and technologically advanced components for a wide variety of applications world-wide. To do this it employs more than 12000 employees in subsidiary and associated companies, in 40 countries around the world.

From its beginnings in 1856, the Group has developed into a world leader in its chosen fields, with an international network of companies supplying markets ranging from electrical, electronics, aerospace, telecommunications, biomedical, healthcare, automotive, rail traction and agricultural, to petrochemical, mechanical engineering, metal melting, heat containment, power transmission, building and site safety.

The Late 1970’s

Operating a business is not easy and few businesses run smoothly. At the end of the 1970s, Morgan Crucible was a very different company to what it has become today. Though long-established, it was a small niche business supplying a few key industrial markets. Many of its operations were dependent upon the performance of customers within the UK. Operating in organisational markets can be a high-risk business. If your customers have problems and your operations largely depend upon key customers operating in one regional market, with such a narrowly defined base you are also likely to have problems. At the same time in world terms, where the key players operate, Morgan Crucible was losing its technological edge. This meant that not only was the business finding it difficult to compete in terms of products and markets, but also in terms of costs.

The late 70s were a critical time for British manufacturers because the period heralded a process of de-industrialisation with the onset of a recession, during which manufacturing industries started to employ fewer people and contribute less to national output. There were many reasons why this process took place. Many UK manufacturers were traditional mature industries, often suffering from low-wage international competition, the high pound and high interest rates, meant that British products were less competitive than competing products from other countries.

This pattern of de-industrialisation in Britain was typical of many major industrialised countries and over the period many famous manufacturing names were lost forever. Some might argue that for some industries decline was inevitable. However, one feature of this process of de-industrialisation was this loss of competitiveness. For Morgan Crucible to be able to survive this period and move forward, it was important to focus upon fundamental questions concerning the whole of the business through a process of strategic planning.

Strategic planning is about focusing upon important questions and issues involving the whole of the organisation’s activities. It is about doing things by taking appropriate decisions and actions, to achieve a range of objectives which tie into a corporate vision. In other words, it is about moving an organisation forward from where it is at a point in time, which for Morgan Crucible, given the realities of the 1970s, meant that key decisions had to be made about the long-term future of the business.

Building a strategy

When it comes to moving forward during an uncertain period, an organisation must have something to aim for, which is a clear definition of where it wants to go. Strategies are simply the means of getting there. It was important for Morgan Crucible to match its strategic direction with its strengths. This would help it to counter threats from within its business environment and yet also be able to take advantage of new opportunities as and when they arose. Morgan’s strengths at the time were:

- expertise in materials technology

- application engineering

- a high potential for new products

- good overseas bases.

These strengths were only part of the picture. No business can be successful without good people and not only did Morgan Crucible have good people, it had good people with good ideas. People were the Group’s greatest asset.

For an organisation to move forward quickly, it has to define where it wants to go, but at the same time set a target which is achievable. Morgan Crucible’s goal was to become ‘World Niche Market Leader in Materials Technology’. The way to get there was through having low cost production and high quality application engineering, whilst at the same time providing technically advanced services coupled with excellence in quality and flexibility in distribution.

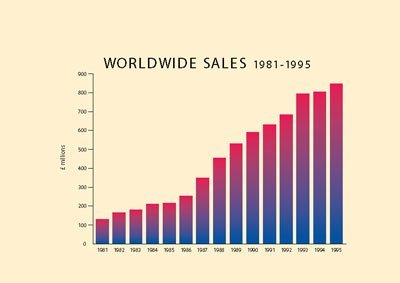

Strategies involve the matching of everything an organisation does to the needs and requirements of their markets. For Morgan Crucible to develop into a 21st century company it had to introduce major changes across the organisation. A significant feature of this process of growth was to be able to develop new materials, products and markets. Sales growth were significant. In 1981 65% of Morgan’s sales were within the UK. By the mid-90s this had fallen to 13%.

Operating structure

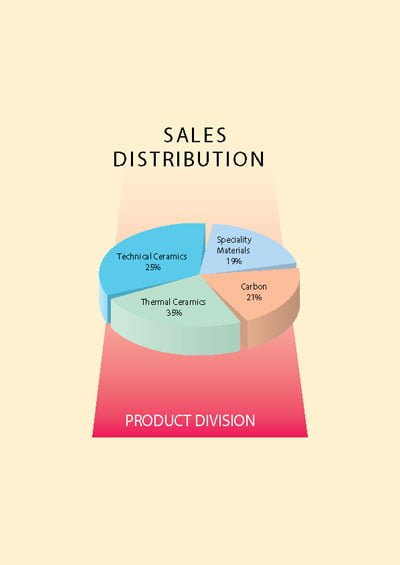

Morgan Crucible’s Product Divisions are divided into four distinct areas:

- CARBON DIVISION – 44 operations in 30 countries. Carbon products account for 21% of total sales. This Division is a world leader in its field, manufacturing a diverse range of electrical carbon materials and components such as brushes used in electric motors for automotive applications, domestic appliances, railways, aerospace and consumer durables. Morgan produces hundreds of special carbon formulations enabling it to make millions of electric motor brushes used in transportation, domestic appliances, power tools and electronically powered equipment in general.

- TECHNICAL CERAMICS DIVISION – 43 operations in 18 countries This accounts for 25% of total sales. The Divisions technical ceramics are specified for the most demanding wear, chemical, high temperature and strength applications in a wide variety of industries. Products range from laser tubes, seals and shafts for pumps and high voltage insulators to infra-red plaques used in high speed industrial heating and cooking. These high purity ceramic components are used in applications as diverse as domestic electric heating appliances, laser systems and, microwave communication products.

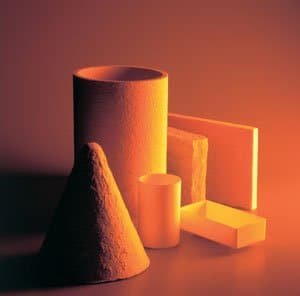

- THERMAL CERAMICS DIVISION – 39 operations in 21 countries. Thermal Ceramics account for 35% of total sales. This Division is the world leader in the development and manufacture of insulating fibre, high temperature insulating bricks and crucibles. The Division’s main markets are the aluminium, steel, ceramics, petrochemical, cement, glass and construction industries. A selection of high performance refactories: silicon nitride melting crucible, high purity alumina assayware and insulating fibre used for high temperature processing applications.

- SPECIALITY MATERIALS DIVISION – 27 operations in 9 countries. This accounts for the final 19% of total sales. The Division manufactures advanced lubricants and industrial and electronics maintenance aids for a wide range of applications. These include corrosion control, fuel conditioning, metal forming and desoldering of printed circuit boards.

Business Philosophy

For this rapid process of growth to take place Morgan Crucible had to change the way it operated. In a complex fast-changing business environment, operating at the frontiers of scientific development, they needed the speed and flexibility which enable specialists to take decisions on the ground. The answer was decentralisation.

Decentralisation is a philosophy of management which involves the passing down of authority and responsibility for the taking of decisions. Delegation is the process of assigning responsibilities and decentralisation is the end result. The process of decentralisation gets decision-making closer to markets, where separately costed units such as subsidiary companies, can respond quickly to market changes. There are many reasons for decentralisation:

- it is difficult for all situations to be understood in detail by people at the top of an organisation. Information forming the basis for these decisions may be complex, varied and specialised and only understood by people on the ground.

- decentralisation cuts the cost of maintaining large central operations. It also creates flatter structures and reduces the number of layers of authority.

- decentralisation allows a swift response to local needs and conditions.

- an organisation which is highly centralised does not allow for individual initiative. A highly centralised organisation is inflexible and involves constant supervision of subordinates.

- decentralisation helps to motivate employees by providing them with more responsibilities and a feeling of involvement with the decision making process.

Today Morgan Crucible operates a very decentralised organisational structure, with subsidiary and associated companies having a considerable degree of autonomy. People are viewed as the Group’s greatest asset and Morgan’s business philosophy is simply – ‘small is beautiful, driven from the top’.

This enables the Group to develop a global perspective, but within this framework the separate companies can act locally with a high degree of flexibility and autonomy for managers. In fact this autonomy is an ownership autonomy, providing individuals with a sense of involvement and tasking decision-makers to operate the separate businesses as if they were their own.

Two measures of any company’s success are the profits it produces and the return it achieves on shareholder’s funds. On the latter basis, Morgan is placed amongst the top companies in the UK. Each of the Product Divisions is headed by a chairman who is a member of the Group Executive and each company within the Morgan Crucible Group has a clearly defined strategy and budget. Three quarters of the subsidiaries are strategically located outside Britain in order to serve their markets more efficiently. Individual profit centres within companies are an important part of the Morgan business philosophy. This structure ensures that accountability in the marketplace is pushed well down the line. A very small head office team at Windsor coordinates this worldwide business development.

Thinking global and acting local

In a business environment which is simple to operate within and static, organisations tend to gear themselves towards operational efficiency by standardising operations and management practices. This whole approach is bureaucratic, suited only to mass production companies. At the beginning of the 80s Morgan Crucible abandoned its mass market activities, such as metal melting, in order to focus upon highly specialised niche markets and products. This changing emphasis required a different way of managing the business. It meant running the business through global product divisions with a shift away from centralised control.

This process of change succeeded in creating a business focused upon developing market opportunities through constant product development, based upon the long-standing specialist knowledge, skills and expertise of Morgan’s employees. Emphasis within the Group was upon the introduction of value-added products in rising demand cycles. In fact 20% of Group sales in 1994 emanated from products developed since 1992.

There were many benefits from this approach. The constant search for profitable product opportunities involves the constant development and tailoring of products to the needs of many separate and distinct markets. This can be contrasted with the marketing of ‘global products’ which serve all markets and assume that needs across the globe are the same. It also allowed Morgan to develop products which related to and build upon the competencies and skills of employees across the Group.

A major feature of the process of change was growth by acquisition and the development of joint ventures. Since 1983 Morgan has bought 90 companies around the world. There has been one strategy with companies only being bought where there was a clear connection by product, market and technology and preferably if there were geographic synergies to be obtained.

Organisational structure

When you develop a decentralised organisational structure, providing subsidiary and associated companies with considerable autonomy, you depend more than ever upon your people. The process of change led to shorter and flatter organisational structures, designed to improve the process of communication and create self-management teams. Within the organisation, this reduced the number of layers to just 5 from the Chief Executive Office to employees working on the shop floor.

The Morgan philosophy is ‘small is beautiful’. The Group comprises many small but focused business units, and, though the largest comprises 800 employees, the average size includes around 120. Within these units, individuals operate each business as if it were their own. This is sometimes called ‘entrepreneurship’, as individuals are provided with the freedom to use their ideas in order to achieve the corporate objectives of each company. The real benefit of this approach is the shared objectives of employees at all levels of management and responsibility, who work together to ensure that their part of the Group is successful.

For this approach to work Morgan has developed a trusting non-threatening open style business environment, which encourages ideas from within in order to develop business opportunities. At the same time it had to create a mechanism in which the ideas could be implemented without the need for a heavyweight corporate structure. Small business units and flatter structures made communication easier from the bottom to the top. If people felt their ideas could work they were given the opportunity to make them work and this is further evidenced by the fact that Morgan has no internal audit team.

In this reactive environment, training and employee development plays a critical role in meeting the objectives of Morgan’s five-year corporate plan – Strategy 2000. Morgan makes a huge commitment to training, with a large annual investment in developing ‘people’ skills for those with the capability and ambition to progress through the Morgan Group, to provide it with its competitive edge. Courses vary from the management of people skills to creativity and problem solving and effective project management. It is the belief from within the Group that its development has largely depended upon the skills of individuals entrusted with management, responsibility and leadership who have sought continuous improvement in a fiercely competitive global marketplace.

Conclusion

Morgan Crucible is an example of a business with a humble past which has developed globally over a difficult period in order to win. In the late 1970s its home market was devastated, yet there was a global demand for specialty products which Morgan had the capability to satisfy. This case study epitomises the transformation of a business over a relatively short period of time, to become a world niche market leader in materials technology.