In the business world of the 1990s organisations cannot afford to remain still. Only 32 of the top 100 of Britain’s biggest industrial companies on The Times list in 1965 could still be found in the top 100 by 1995. All companies, large and small, have to be alert to the threats and opportunities that could make or break them. Change is about remaining ahead of the competition. It is about developing and moving on. Organisations that do not alter and re-shape themselves often fail.

Over the years, the steel industry has had to cope with great change. In more recent times, world-wide over-capacity and advances in technology have accelerated the change process. During the last thirty years, British Steel has consolidated its position as one of the world’s most efficient manufacturers. In 1967, when the major part of the steel industry was nationalised, British Steel Corporation employed a quarter of a million people. Returned to private ownership in 1988, British Steel now employs less than 50,000 people. Millions of pounds have been invested in plant and equipment, new working practices and the education and training of employees to create a Total Quality Performance environment.

Total Quality Performance encourages a continuous cycle of improvement. It aims to make ongoing improvement part of organisational life, focusing everything an organisation does on the customer. This case study examines how one part of British Steel has responded to its changing business environment to become a centre of excellence. It describes how a range of initiatives and developments has helped British Steel’s staff at Shotton Works to improve their customer focus and take responsibility for enhancing their performance while further developing their own career opportunities.

Shotton Works

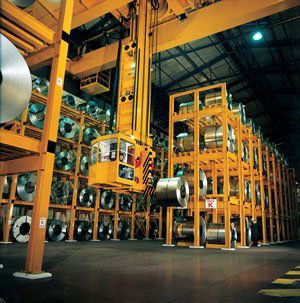

Coated Products are used mainly in the automotive, construction, domestic appliance and teletronics industries. Steel strip covered with metallic coatings and specially formulated paints for corrosive resistance and colourful finish, can be found almost everywhere in everyday life – in homes, offices, factories, schools… British Steel is a world leader in the production of coated steel.

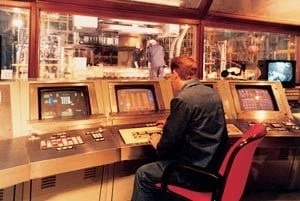

Shotton Works is British Steel’s main operational site for Coated Products. Extending over 500 acres in Deeside, North Wales, it is part of British Steel Strip Products and the operational headquarters for a group of works specialising in the manufacture of coated products. It comprises cold rolling facilities, hot dip coating lines, electro-galvanising lines and organic paint lines with a combined capacity of over one million tonnes per annum.

Developing customer focus

In a rapidly developing market-place, it was important for British Steel to devise a strategy which matched the activities of the organisation to the environment in which it operated. This process is known as strategic fit. Shotton’s future depended on the ability to produce competitive and innovative products for the needs of domestic and international markets. This meant looking outwards at changing markets, business conditions and competition and then using this knowledge to develop the organisation to meet customer requirements.

Strategies operate at a variety of levels to involve everybody within an organisation. At the highest level, strategic decisions have helped British Steel to become one of the largest steelmakers in the world. Operational strategies follow on from the overarching strategic direction of the organisation. They are concerned with how the key parts of an organisation in terms of people, resources and processes, are pulled together to meet this overall mission.

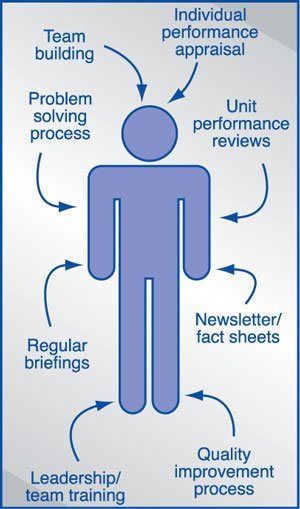

Changing the culture of an organisation is a difficult and slow process. As the same raw materials and technologies were, and still are, available to all steelmakers, it was realised that the only way to differentiate British Steel from its competitors and give it real customer focus was through its employees. Systems, procedures and technology alone do not provide any guarantees, but quality people can. For the employees at Shotton this has involved:

- total quality performance

- self managing work teams

- benchmarking.

Total quality performance

Quality refers to the individual characteristics of each product or service that enable it to satisfy consumers. The consumers’ perception of the quality of a product or service is one of the most important factors in determining its success. Total Quality Performance goes beyond quality assurance. It is concerned with creating a quality culture so that every employee will seek to go beyond just satisfying customer requirements. The customer thus becomes central to the production process.

In 1991, senior managers at Shotton Works gave a commitment to develop a total quality culture, by learning lessons from other companies, not necessarily in the steel industry, and seeking best practice, whatever that might be and wherever it might be found. The primary objective was to meet customer requirements and expectations through improved performance and the elimination of defective work. The programme required a commitment from every employee to the Right First Time philosophy.

To produce a strategy for total quality the management committee considered the following questions:

The total quality programme began with a series of awareness workshops for everyone across the organisation. More than 2,000 employees were introduced to the principles and philosophies of total quality. Quality Improvement Teams (QIT) were set up to run alongside the workshops to address important quality issues. Emphasis was placed on the processes of quality improvement and problem solving. By improving processes and quality, these teams generated many ideas which made substantial savings for the business – £12 million in six years.

Learning from mistakes and attacking problems where they occurred were critical to the growth of a learning culture. The total quality programme also developed an awareness of the need to improve the speed of the organisation in managing change. There were a number of problems such as:

- an inconsistent manufacturing strategy

- conflicting objectives

- personnel blinkered by old ways of working and thinking.

People needed to understand where the organisation was going and what it was trying to achieve. A clear vision which could be understood by everybody needed to be established. This was provided by the publication of a vision statement ‘to be our customers’ preferred supplier’ and further by the establishment of critical success factors (CSFs) against which some form of measurement could take place. These CSFs were:

- high customer satisfaction

- process efficiency

- maximum people contribution

- optimum cost effectiveness

- excellent business systems.

The achievement of the CSFs, and therefore the success of the business, is underpinned by a comprehensive employee education and training programme, notably in the following areas:

- problem solving and quality improvement

- annual performance appraisals for everyone

- measurement of all key operations and targets.

The total quality philosophy helped to break down old barriers, promote consistency and challenge the old way of doing things.

Working in teams

As a further development of the total quality process, teamworking was introduced in Shotton Works in August 1995, under the acronym TOPICS, Team Orientated Programme for Improved Customer Service. The objective was to equip and organise the workforce to enable better understanding of the processes and bring about Right First Time manufacturing by eliminating the opportunities for error. Teamworking relies on trust and people working co-operatively together. It provides a mechanism for interaction between people carrying out different functions but with a common purpose. Effective teamwork is recognised as a key feature of successful organisations today.

From the start of the programme, it was realised that the benefits of teamworking would not appear overnight. However, it was planned that the process would, over a period of time, lead to better product quality, increased plant availability and a higher level of deliveries on time. It would also enable British Steel’s Shotton Works to develop a highly skilled workforce which would achieve and maintain a leading edge over its competitors. Five integrated manufacturing teams, centred on specific production lines and involving around 1,000 employees, were developed as part of a collaborative effort between management, trade union representatives and all other employees.

All production employees were asked to apply for team positions. Members were selected from people already employed in existing production areas and others with the appropriate skills. The selection process involved a series of written tests and face-to-face interviews. Switching to new tasks and working practices can sometimes be difficult, especially for those who have operated in a particular way for a long period of time. Those selected for teams followed an intensive training programme averaging thirteen weeks over a year. Six of these weeks were ‘off the job’ and based in a classroom. A number of personnel issues, such as job grading structure, trade union representation and rates of pay, had to be resolved as part of this process. One key advantage was that team membership and promotions were now based on competence and proven ability rather than length of service. Continuous learning was also recognised as an important part of the training process.

The team structure was simplified into a shift manager supervising working section leaders and team members. The shift teams were supported by day managers and others with specialist knowledge, such as engineers. The team approach made the structure of the organisation much flatter, with fewer levels of authority, and less hierarchical. De-layered structures, developed through self-managing teams, helped to empower employees, making them more responsible for their own actions and allowing them to participate more in decision-making. They also had more freedom to put their training and experience into effect.

The benefits of team working

A number of key benefits resulted from teamworking, including job enrichment. Job enrichment involved giving people more responsibility and recognition, thus helping people to feel that their contributions had been upgraded and were more appreciated. There was also the opportunity to earn more money for new skills through a ‘personal competence supplement’ to their pay. The use of Open Learning programmes, i.e. any type of learning undertaken in the employees’ own time, but mostly PC based, increased ten-fold between 1992 and 1998. More recently, the LEADS (learning and development opportunities at Shotton) initiative was introduced to encourage employees to extend their knowledge and pursue both vocational and non-vocational qualifications. Other benefits included:

- better communications

- a more positive approach to work

- less down time/waiting time

- improved knowledge of engineering issues as well as knowledge of the plant and processes

- improved documentation

- service functions (e.g. Personnel, Quality Control) focused on supporting the manufacturing process.

All of these improvements are measured to monitor progress and quantify the benefits to the works. It is important that the measurement of performance and other standards are always forward-looking. The development of teams helped employees focus on both personal and team issues such as the achievement of quality, customer satisfaction and productivity. Right First Time and Service Level Agreements between manufacturing teams and internal supplier departments such as engineering, accounts and technical, also served to maintain a focus on key issues. Service Level Agreements are ‘contracts’ within the Works to ensure that the product or service provided by the supplying department is that which is required by the receiving department. The constant reviews of personal performance and the achievement of objectives helped determine promotion prospects and progression through each team.

Results of team working

The results from the team working process over the first three years were impressive. With fewer people, the new manufacturing teams achieved around 4% increase in productivity, increased product yields by an average of more than 4% and both accidents and customer complaints more than halved. Employee suggestions for improvement had tripled to an average of more than one per employee per year. Overall, the massive savings for the plant increased both its efficiency and competitiveness, measured through internal Service Level Agreements, as well as the key business performance indicators and critical success factors. At the same time, it provided employees with the chance to increase their skills, maximise their own potential through self-development and make a positive

contribution to improved business performance.

Benchmarking

As part of the process of improvement and development, British Steel has used benchmarking as part of its strategic programme of quality improvement. Benchmarking is an approach which has become increasingly popular in recent times for organisations wishing to improve the quality of their goods and services. It involves identifying best practice in a particular sector, industry or group of organisations and then seeking to match or exceed that practice to lead the field.

Benchmarking at Shotton Works was used to explore its key business processes. After visiting many companies which were experienced at benchmarking, Shotton developed its own benchmarking process:

- Identify process

- Select team

- Train team

- Analyse process

- Measure the process

- Action the obvious

- Internally benchmark

- Identify sources/partners

- Obtain data

- Compare measures of performance

- Identify the gaps

- Identify improved practices

- Develop action plan

- Implement action plan

- Monitor and report.

This framework was used initially to analyse the storage and control of steel stock. Teams, led by senior managers, mapped processes such as order to cash and procurement to distribution. Magazines, consultants and personal contacts were used to collect information. Companies with reputations for good practice in this area were also visited.

The work of the benchmarking teams helped identify many areas for improvement, in terms of time, quality and efficiency and thereby increased the capability of processes to deliver Right First Time products and services.

Conclusion

Continuous improvement never stops. Shotton Works has become a centre of excellence which is dedicated to improving the standards of its products and services to customers both within the Company and externally. Teamworking and benchmarking have helped employees to become more involved with this objective and to focus on the long-term needs of a continuously changing and competitive international market.

There have been many learning points from these experiences. The importance of Just In Time training, the building and development of skills and the use of information technology have all been emphasised. The next stage will involve further management teambuilding, the continuous development of employees’ skills and the restructuring of service departments.

Although the process of change may initially frighten those it affects, good communication and the establishment of an atmosphere of trust help provide a shared understanding of business objectives. In an educated and wellinformed business environment, such as that at Shotton, where individual and team skills have been established and developed, living within a change environment has created a learning culture where everybody’s contribution is vital to the further growth of the business.