When Michael Marks and Tom Spencer became partners in 1894, they could not have imagined what they were creating. Their energy, drive and enthusiasm laid the foundations for the development of a business, which has now become one of the UK’s leading retail chains with a unique market position. Millions of people shop in Marks & Spencer every day and to these millions, Marks & Spencer represents a range of thousands of exciting products of the highest quality and outstanding value. In the UK, Marks & Spencer’s operate 285 stores of differing types:

Departmental Stores 39

Town Centre 206

Edge-of-Town or Neighbourhood 40

Additionally, on a worldwide basis, there are a further 88 stores as well as 78 franchise shops. Marks & Spencer also owns Brooks Brothers which has 157 shops in the USA and Japan, and Kings Super Markets with 20 stores in the USA. Any business that becomes a household name, creates customer expectations and customers are now far more knowledgeable, sophisticated and demanding. In a changing world, a retail organisation’s ability to meet these expectations is not only a function of the products it offers but also depends on how it approaches and provides the needs of its customers.

In order to satisfy these requirements the company needs to respond flexibly. This necessitates some stores opening between 7.00am and 10.00pm so that when a customer enters a store, he or she can expect to find a full range and choice of products, from baked beans to fresh produce ranges, recipe dishes and exotic foods. This variety has to be available seven days a week, in all locations, at all times of the day and night. As an example, on a typical day the company’s flagship store at Marble Arch, London, attracts more than 50,000 customers and therefore meeting the expectations of every customer is an important part of Mark & Spencer’s founding principles of quality, value and service.

Marks & Spencer brand products are sold in their stores under the St Michael name. The stores are designed to provide an attractive and well laid-out shopping environment, which provides the highest level of customer care. Each day more than 200,000 trays of stock are scheduled to arrive at the correct location, in the right quantities required having been distributed through Marks & Spencer’s distribution network, in order to satisfy customer needs. It is not difficult to imagine the complex nature of this network and some of the decisions which have to be taken.

Behind the Scenes

This case study focuses upon one aspect of the physical distribution activities ‘behind the scenes’ at Marks & Spencer. Physical distribution involves all the essential activities required to make products available for customers and is a fundamental dimension of customer service. It is a formidable challenge for management when one considers the number of items on display on the sales floor and if these were to be multiplied across all stores, it becomes clear that the successful stocking of a sales floor is logistically complex.

Efficient stock management enables Marks and Spencer to provide customers with the service they expect by maximising the availability of the products they require. The key to developing an efficient system of stock management is that of stock accuracy. This case study looks at Food Stock Management, a computerised system introduced by Marks & Spencer, which enhances key information enabling them to respond swiftly and flexibly to supply issues in order to meet customer needs.

Suppliers

Marks & Spencer has been selling food for 70 years. The founding principle has been to sell food of outstanding quality offering good value for money. The range of merchandise includes:

- Fresh Produce

- Ambient (non-refrigerated merchandise/long-life dry goods)

- Cold Chain

- Frozen

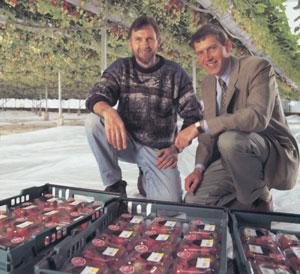

In total these amount to many thousands of lines. To support these lines there is a continuous and energetic process of new product development. Each year a large part of the product range is relaunched, upgraded or repackaged. One of the key aspects of Marks & Spencer’s food business is the relationship which the company has developed with its suppliers, covering a range of areas including production and manufacturing techniques, reduction in lead times, resulting in improved quality levels. Marks & Spencer source their ingredients from around the world and to ensure quality and value, work closely with suppliers at each stage of production thereby ensuring hygiene and freshness. This can be exemplified:

- Vegetables picked in Kenya on a Monday will be on sale in Marks & Spencer by Wednesday, only 48 hours after being picked.

- Marks & Spencer’s fleet of fishing vessels ensure fish is frozen within six hours of being caught.

- Marks & Spencer strives for quality, never offering anything other than first quality merchandise for sale.

- Marks & Spencer works with suppliers to develop technologies which drive quality and availability.

- The starting point for Marks & Spencer dishes is the very best food from the very best chefs and the best restaurants.

- Marks & Spencer strive to be innovative in food process development – they found a way of placing meringue onto a mousse without the meringue going soggy!

There are many routes to developing new food products. The starting point occurs when Marks & Spencer selectors provide a brief for suppliers, comprising a range of ideas for research and development. Ideas originate from changing food tastes as evidenced by the increasing number of different types of restaurants from around the world or from food selectors spending time abroad examining alternative cuisine and dishes. Other opportunities are developed having identified local trends, as occurred in Scotland where Marks & Spencer managers and supervisors noted there were products required by Marks & Spencer customers which the company did not offer. Their research led to the development of the ‘Haggis, Neeps (turnip) and Tatties (potato)’, the traditional Burns Supper as a national line. In the north-east of England they offer customers ‘Stottie Sandwiches’ (a savoury filled large bap) and in other areas, they offer food gifts specifically developed for visitors to a region. Recently, the Marks & Spencer food business has grown at a faster rate than its textile business. This growth has reflected changing shopping tastes and trends leading to them altering the balance of merchandise in departmental, town centre and edge of town stores.

Retail technology

Retail technology permits retailers to evaluate sales trends and match them to customer needs. Marks & Spencer remains at the forefront of retail technology. It utilises technology and management information across a wide spectrum of activities thereby responding to changing customer requirements. Each time a purchase is made, the Marks & Spencer electronic-point-of-sale (EPOS) till does a lot more than produce a receipt, it links stores to the distribution network by recording sales, adjusting stock and providing information to influence buying decisions.

EPOS information also helps to develop shape of chain’ information for each Marks & Spencer store, by identifying products which sell well and takes into account the different sales patterns throughout the chain, including seasonal variations and consumption trends. This helps Marks & Spencer to monitor customer spending, avoid out of stock positions and generates specific sales and marketing data.

Food Stock Adjustments (FSA)

The process of satisfying customer requirements, through physical distribution activities, is more complex than just ensuring goods turn up at the right place at the right time. In a perfect world, stock arrives promptly, is in good condition and is sold quickly thereby negating expiry dates. However, we do not live in a perfect world, therefore stock adjustments are a necessity to ensure the maintenance of satisfactory stock levels.

There are a number reasons why stock adjustments need to take place. Stock levels need to be adjusted where food has gone beyond its expiry date (DEF) or when food is returned to the manufacturer (RTM). This may be due to damaged packaging, too much fat on a joint of meat or simply that the product has not met quality requirements and will not be made available for sale. Further adjustments take place when stock is transferred to other stores.

In the past, the process of stock adjustments took place through a system known as Food Stock Adjustments (FSA). This involved some completion of paper records for RTM, transfer and self supply and keeping duplicate copies. The process was time-consuming and provided limited information for very few users and was often difficult to trace.

A merchandiser needs good management information to enable him/her to understand a problem when it arises and the reasons for the problem developing. If, for example, on the previous day an RTM for £250 occurred on poultry and had been recorded, the merchandiser would want to know it had occurred. Recording the reasons for this RTM using a paper system would have meant that the information was out of date before the paper copy reached the head office buying department.

A time for change

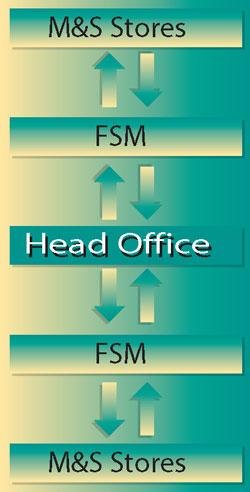

It was generally recognised that the Food Stock Adjustment process did not meet Marks & Spencer efficiency objectives of providing all users with the information they required quickly enough. Food Stock Management (FSM) was developed to replace the FSA, through greater use of technology and eliminated the use of paper and manual recording procedures. FSM provides a system for the recording of all food stock adjustments and non sale movement of stock to maintain stock accuracy.

Hardware included the use of new user-friendly hand-held terminals (HHTs), which recorded and transmitted bar code information to a windows-based PC and a keyboard held in each Marks & Spencer store. HHTs are simple easy-to-use scanners which use bar codes to record information. Information is transmitted to a store processor before being sent to Head Office through a wider area network, connecting computers on different sites via modems to a centralised information system providing access to managers. FSM:

- eliminated manual books such as the RTM Book, the Self Supply Book and the Transfer Book.

- produces a series of key reports including, price checking report, product changes report, stock record report, daily activity report, shortcode and produce report, interim accounting report, all of which are used by stores for information purposes.

Additionally, these key reports produce a number of benefits for management giving them the opportunity to, more effectively, manage the store. Some of these benefits are as follows:

- reports can be viewed as well as printed;

- runs an automatic Start and End of Day;

- increases staff accountability;

- improves stock accuracy;

- stores more able to respond swiftly and effectively to sales trends.

Food Stock Management enables data to be captured from Marks & Spencer stores and provides a valuable source of information on which well informed management decisions can be made. It provides access to better quality information for a larger number of users and improves the way Marks & Spencer responds to customers. Benefits include:

- on-line information

- reduction in paperwork

- improved centralised and decentralised control

- ability to investigate problems and stock issues

- leading to…IMPROVED CUSTOMER SERVICE

Food manager

The FSM workstation may be located in the Administration office adjoining the Food section or in the Administration Centre and is used by:

- Food Commercial Managers (for probing)

- General Staff via HHT (to record sell outs or action corrected stock counts)

- Administration Assistants (to access stock record information regarding sterling value of

- deliveries)

- Food Supervisors (to authorise RTM’s)

The system has access at different levels, each of which is protected by a password system. FSM plays an important part of the everyday role of the Food Manager. The first job of the day for him/her is to make sure that the Food section is full, presentable and ready for opening. On a daily basis managers examine the amount of date expired products and quality waste generated for the previous day. Stores are given waste percentage targets for the year which must not be exceeded. FSM is a tool to ensure that stores are probing waste and RTM levels.

Quality, Value & Service

M&S’s priority for its customers is having quality products in the right place at the right time. This is also the key objective of FSM. Marks & Spencer is committed to putting the customer first at all times. This involves selling merchandise of the highest quality at outstanding value and providing good customer service. Initiatives such as Food Stock Management enable Marks & Spencer to:

- improve the efficiency of operations;

- improve the quality of products by providing better information for suppliers;

- reduce the cost-base of operations and reflect the benefits by improving value for customers.

Conclusion

Moving from Food Stock Adjustments to Food Stock Management was not achieved overnight. It was recognised that technology could significantly improve the process of stock adjustments, but development had to take place carefully and sensitively to ensure that the company would reap the required benefits.

Food Stock Management is a good example illustrating how a process of change can deliver the required benefits. It has led to a reduction in paper and has increased efficiency through access to better management information. It has also released sales assistants time so they can focus on providing customers with the services they require.