“IF YOU CAN INVENT A BETTER MOUSETRAP THE WORLD WILL BEAT A PATH TO YOUR DOOR!”

Many of the best business lessons are based on the intelligent application of common sense. However, our own experience of everyday life suggests that people and organisations often fail to apply common sense. The statement “If you can invent a better mousetrap the world will beat a path to your door” can be used to illustrate sound business wisdom. Organisations today operate in highly competitive situations. In this environment, some organisations lose their way by sticking rigidly to existing products and business methods. They fail to recognise the need for change. Organisations which achieve the most successful growth patterns continually seek to improve and lead the field – they are seeking that ‘better mousetrap’.

This case study focuses on how FKI created an innovative new product which yielded outstanding benefits to its customers – the electricity supply industry.

Organic growth

Charles Handy, a British business expert, has frequently stressed the importance of growing a successful business. He argues that the most important time to introduce change and innovation is when the business appears to be most successful. A business that grows complacent may appear to be riding the crest of a wave but may actually be on the edge of a trough. An intelligent organisation continually seeks to design better products. Organic growth involves developing new ideas and products from within the business.

New and successful products can be sold to the market at a premium price – i.e. one that reflects value for money through high quality, rather than having to sell products at discounted prices because they are not differentiated from those of rivals.

FKI operates in what is termed an inelastic market for many of its products. An elastic market is one in which it is possible to increase demand by reducing price. For example, if the price of chocolate is halved, it is likely that more chocolate will be bought – it is an elastic market. However, if the price of cookers is halved, demand will not increase significantly as most households have only one in the kitchen. A price decrease in an inelastic market will not generate significantly increased sales because the price reduction will rapidly be matched by competitive sellers. The key to success in an inelastic market is to create better products which are clearly differentiated from rival products. The better product is more desirable and therefore, the customer is prepared to pay a higher price.

Creating a new product

Electricity is distributed in rural areas by the use of bare aluminium conductors supported by wooden poles. This method of electricity distribution is used world-wide, particularly in rural areas where the use of more expensive (but less visually obtrusive) underground cable cannot be justified due to the length of the line and the relatively low amounts of electricity supplied.

A disadvantage of such overhead line systems is that they can be subject to a large number of faults caused by obstructions on the lines (birds, tree branches etc.), by the touching of the lines in high winds or the failure of insulators. Most of these faults are temporary and will disappear once the current is re-established after a short interruption. To keep system interruption down to a minimum, pole mounted auto-reclosers are used.

Essentially, an auto-recloser is a poletop mounted reclosing circuit breaker which is used to protect sections of the overhead line supply network, usually in remote locations. An electronic control unit operates a mechanism which opens the main circuit contacts when it detects faults in the current supply on the overhead lines which it monitors. It then recloses. If the fault is still present, the auto-recloser will open and close two more times before finally locking out. If the fault has cleared, the auto-recloser sequence ends with the main contacts closed and the supply re-established. Auto-reclosers must be highly reliable and require little or no maintenance because they are:-

- intended to improve the reliability of the distribution network.

- unlike other forms of protection device which very rarely operate, an auto-recloser’s normal duty is to operate many times under fault conditions.

- installed in remote locations of the network

Product development

FKI continually seeks to improve all its business areas in order to remain at the head of the field. By creating a new device to protect electricity supply infrastructure in remote applications, FKI was, in effect, building on previous technology in this field. FKI however, sought to create a giant leap forward in product technology that would distance the Group from the competition.

Techniques for reclosing overhead line supplies are not new – they have been performed manually and automatically for a number of years. However, FKI wanted to create an innovation in automatic reclosing. The new reclosing device that FKI developed is called a Gas Filled Vacuum Recloser (GVR). The new generation of switchgear is innovative because it uses new developments in rare earth magnets in a brand new operating mechanism – overcoming the problems encountered in earlier designs. The new mechanism forms the basis of a low maintenance, low power consumption unit which can be installed in remote inaccessible areas. It is independent of external supplies and has been tested for unattended use equivalent to 10 years in service.

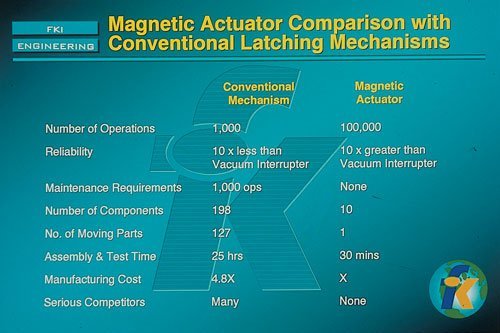

This case study does not set out to give a detailed description of the technologies involved in creating the new GVR. However, it is important for students to be aware of a number of key measures of improvement the new device has created in electricity distribution. These improvements are encapsulated in the chart. The figures indicate considerable performance improvements and show why the device has been so popular with customers.

The technological advance made is a combination of several major innovations which are applicable to all types of high power switchgear. They have been used for the first time on the GVR to make it the most revolutionary item of switchgear to have been developed for many years. Other functional advantages not shared by competitive equipment:

- Rubber bushings rather than porcelaine, resist vandal damage.

- Interrogation & two way communication via satellite, cellular telephone or fibre optic cable.

- Aluminium rather than steel, lightweight, no painting (very important with high voltages).

- Lightweight for easier installation & transportation to site.

- Batteries & control at ground level ensure independent supply.

- Vacuum switching, no byproducts, environmentally friendly.

- Filled with SF6 insulating gas to reduce size.

Customer appeal

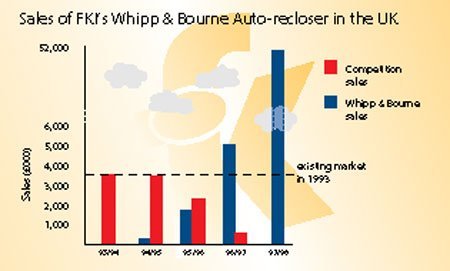

In the final analysis, the success of a market driven company is measured in the way in which the customers respond to the product. It is therefore necessary to examine whether customers have chosen to buy FKI’s new device or not. The results show that, since its launch in August 1994, GVR sales have increased dramatically:- Orders received in the first three months of 1997/98 are in excess of £13 million. Whipp and Bourne Ltd (the FKI business responsible for the development) has taken virtually every order placed in the UK by the regional electricity companies over the last two years. Export sales are currently to South America and the Far East and an American manufacturing arrangement is being negotiated. The technology is now being extended to encompass a range of switchgear before being extended into new applications.

Conclusion

Whipp and Bourne Ltd was able to create and develop the GVR through the skills, expertise and innovation of its engineers. Great engineering lies at the heart of many key innovations and products that have driven this country forward since the days of the industrial revolution.

In 1993, Whipp and Bourne Ltd established a special project team with the task of steering this breakthrough in thinking. The group was supported by development, test and manufacturing personnel. Discrete components in the design were tackled simultaneously by a separate team thus leading to rapid progress. The team also drew upon the expertise of external sources including moulding and materials specialists, tool makers and battery manufacturers. The key personnel were all relatively young but each had considerable engineering expertise and skills. They were:

- Stephen Lane (03/01/57) Engineering Director of Whipp & Bourne Ltd.

- Martin Snell (30/04/56) Chief Projects Engineer, Whipp & Bourne Ltd.

- Alan Shephard (20/07/64) Chief Projects Engineer, Whipp & Bourne Ltd.

The team initially identified and examined the main weaknesses in existing devices. They then identified the main difficulties which needed to be overcome in the design of the revolutionary new device. This meant working with a ‘can do’ approach. For example, the main difficulty which had to be overcome, was to design a mechanism which would power the auto-recloser for a minimum of 10,000 operating cycles, over a period of ten years in extremes of temperatures (+70°C to -40°C) from a cost effective primary battery.

The team members were given freedom and responsibility to deliver the solution and, by adopting a positive approach, ensured the GVR became a major success. This led to high levels of individual satisfaction balanced with rewards of a monetary nature.

This case study shows how FKI was able to ‘build that better mousetrap’ – developing an exciting new product which has created a significant breakthrough in the industry in terms of performance, cost and reliability. FKI succeeded in differentiating the product rather than through discounting the price. This has been the pathway to develop and enhance the long term reputation of the business.