We live in a digital age. Music, video, phone calls, information creation and information consumption are all, by and large, done digitally. A huge proportion of this happens on the Internet.

People use the Internet and its content via computers: As Internet content becomes more sophisticated with, for example, film, music and podcasts, more computing power is needed. The computer chips inside computers need to keep pace with that demand.

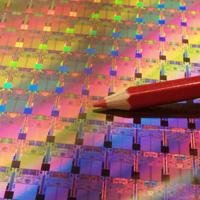

Computer chips are essentially collections of transistors – tiny electronic devices that control the flow of electricity to create the 1s and 0s that underpin computing. Intel is the world”s leader in silicon innovation. Silicon is made from purified sand that is super-heated. Produced as a huge sausage-like shape called an ingot, it is sliced into wafers.

Intel is best known for producing the chips that deliver this increased computing power. The chips are manufactured on these wafers. Transistors are the building blocks of computer chips that Intel has been making for 40 years. Intel has been working to make these transistors smaller so that more of them could be fitted onto the same area of silicon, making the chips more powerful. This came at a price. Until recently, the smaller the transistors, the hotter the chips tended to run.

In 2007 Intel developed a breakthrough in the materials used to construct the transistors. Not only can these transistors work faster, they can also do this while generating less heat. Intel has started to use this new material for its latest generation of processors. These are made from transistors only 45 nanometres in size. This means over 2,000 of them could fit on the full stop at the end of this sentence. A 45 nanometer transistor can switch on and off approximately 300 billion times a second. A beam of light travels less than a tenth of an inch during the time it takes a 45nm transistor to switch on and off.

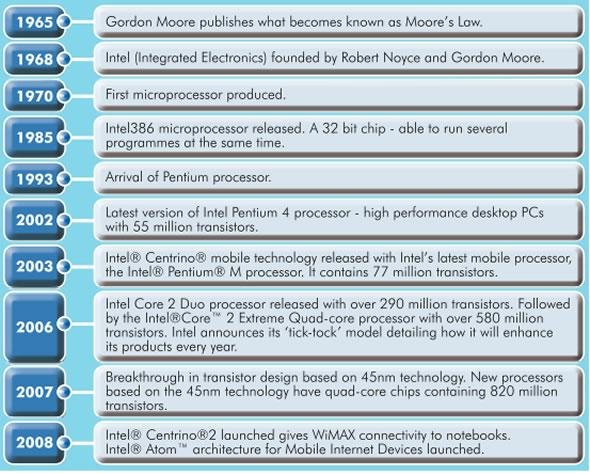

Gordon Moore, Intel’s founder, predicted that the number of transistors on a chip will double roughly every two years.

Intel uses ‘Moore’s law’ to inform its development strategies. This case study focuses on Intel”s integrated mix of research and development (R&D) and manufacturing. This enables Intel to implement the ‘tick-tock’ strategy designed to put it ahead of its competitors and maintain that competitive advantage.

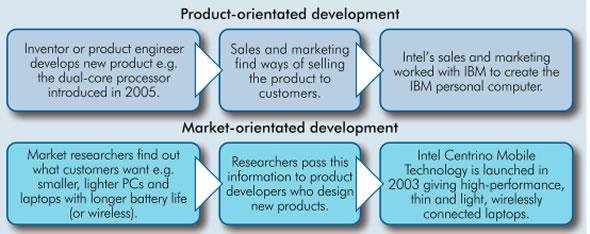

Market or product orientated development

A business can develop its products either through product-orientated development or market-orientated development:

- product-orientated development focuses on developing the production process and the product itself arising from, for example, new use of technology or innovation a market-orientated approach identifies and analyses customer needs. It then develops products which meet them.

Both approaches are important.

Right from its early days, Intel realised the importance of combining product innovation with a market-focused approach. Intel responds to both customer demand and product innovation. Its products are therefore ‘user-centric’, that is, the product development meets the needs of the customer.

Intel has anthropologists who study how people use technology in their lives. This information helps Intel’s product design teams to understand what customer requirements are.

Intel also has a development programme to increase the capacity of a microprocessor. This fits with the two-year cycle in which the microprocessor is adapted or a new product is launched.

Research and development

Research and development help to:

- create new and better products

- improve the methods for making the products

- develop new market opportunities to sustain or accelerate growth.

Research

Research involves designing new ideas to solve a problem or to create an opportunity. An example is the development of a new microprocessor for a mobile phone to give it access to the Internet.

Intel conducts research in two key areas:

- research into manufacturing capabilities and material. This type of research led to the introduction of the 45nm high-k metal gate silicon manufacturing technology and more broad research focused on what technology can offer. This can cover how to integrate multiple different types of wireless technology into a single device or how to use silicon technologies to act as sensors. The research reaches into areas such as robotics.

Intel invests large sums in its research laboratories all over the world.

Intel’s leadership in silicon technology, combined with the R&D capability to develop new products and new ways of making products, makes it one of the leaders in its field.

The result of this research is the creation of products customers want, which can be manufactured easily in large volumes. Examples include notebook computers containing Intel Centrino Processor Technology.

Development

Research generates many ideas but only the best will be chosen for development.

Development involves converting good ideas into a commercial product, for example, by improving a microprocessor to run multiple computer programs at the same time. The development of the selected products must meet specific timetables for launch worldwide.

The end products resulting from an intensive R&D programme benefit the customer. These might include a smaller and faster computer or mobile phones at lower prices. Technological advances can also mean less energy consumption, reducing the carbon footprint of consumers and businesses.

Before manufacturing, Intel produces a ‘blueprint’ or design of what a particular microchip will be needed for. This outlines all the functions it will need to support, such as wireless capability or image software. The design has to answer key questions:

- What type of chip is needed and why?

- How many transistors can be built on the chip?

- What is the best chip size?

- What technology will be available to create the chip?

- When does the chip need to be ready?

- Where will it be manufactured and tested?

To answer these questions, Intel works with customers, software companies and Intel’s marketing, manufacturing and testing staff.

Intel takes all the responses to define a chip’s features and design. The designs are put together in the form of a computer-simulated chip that can be tested using Computer Aided Design (CAD). The CAD system tests, for example, how the transistors turn on and off. It also tests how the chip performs an action such as launching a computer operating system.

Manufacturing

Intel has been described as a ‘manufacturing monster’. It can develop and bring a product to market faster than anyone else. Intel”s production process is automated using sophisticated robotic equipment to ensure accuracy. This is a good example of production in the secondary sector of industry.

Intel has plants around the world manufacturing different processors for different markets. It chooses locations where there is enough land to build such large plants. These need to be close to skilled labour, its markets and to customers. For example, Intel fabricates 45nm chips in New Mexico, Oregon and Arizona in the USA, as well as in Israel. Each new factory costs up to $3 billion (around £1.5 billion) to construct. The refitting costs for older plants can be over $1 billion (around £0.5 billion).

Intel uses a methodology called ‘copy exactly’. This ensures factories are built in exactly the same way, no matter where they are, and gives a consistent approach. This is critical when manufacturing such sensitive and highly complex devices. It takes an average of 200 people working full-time for two years to design, test and have a new chip ready for manufacture.

The manufacturing process requires the highest standards of ‘clean environments’. This is thousands of times cleaner than in an operating theatre. Intel’s employees wear special suits to ensure no dust or hair falls onto the wafers. The air is so clean that one cubic metre of air contains less than one particle of dust. The production process is a highly complex one.

Market segments

Intel provides computer chips for many different market segments. A market segment is usually defined, for example, by age, gender or geographical position.

Intel identifies its market segments by product use, e.g. notebooks, desktops, servers. Some products are for the business market, for example, desktop computers and laptops for companies. Other products are for personal use, for example, notebook computers for students.

Vertical integration

Intel is continually developing new approaches to keep it ahead of the competition. Vertical integration gives Intel a strong advantage. This means Intel does not outsource any of its work for research, development or manufacturing. For example, many companies do research and some development but give the product design to another company to produce.

Intel does all three processes itself. Its manufacturing process is capital-intensive because of the specialist equipment. For example, Intel spent more than $7 billion (£3.5 billion) on manufacturing plants using the latest 45nm process technology. Intel believes this investment is worthwhile, as this highly competitive approach gives it a competitive edge by:

- ensuring quality

- protecting its ideas

- meeting its timescales.

Competitive advantage

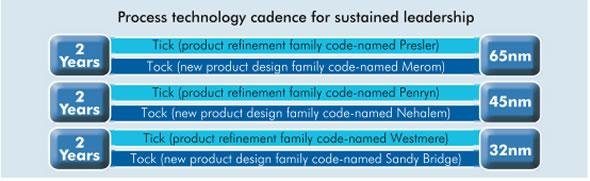

Competitive advantage means a company has or does something better than its rivals. The Intel ‘tick-tock’ strategy was announced in September 2006 by Intel’s CEO, Paul Otellini. It is a blueprint for Intel to maintain its technology leadership and competitive advantage. It plans to take advantage of Intel”s product research, development and manufacturing capacity to deliver improved products every year.

This regular improvement will ensure continued market leadership. In ‘tick’ years Intel will introduce a new manufacturing process (of which the 45nm process is the latest). ‘Tock’ years will see the introduction of new designs (architectures) of CPUs (central processing units).

Intel is competitive because:

- it has a regular cadence (or rhythm) to the development of new products or improvements to existing ones

- it integrates teams from R&D and all areas of manufacturing, all working to the same schedules. Intel is the only company that can combine and optimise manufacturing process technology, product design, leading-edge capacity, design tools, masks and packaging in-house

- it sets the highest standards in high-quality clean production. The company invests vast sums in R&D and manufacturing. This makes it is difficult for rival companies to match Intel

- it designs quality products. Intel continually develops new technologies that combine product-led, user-led, and market-led features

- it is able to leverage its manufacturing capability. This means it can increase production to bring product to market in large volumes. Increasing volume and getting the product onto the market as quickly as possible are important elements in creating and maintaining a competitive advantage.

Intellectual property

In order to protect its advantage, it is essential that Intel registers intellectual property and patents in new product development. This registration is vital for Intel. This gives legal protection against copying by its competitors.

The protected time allows it to sell its products without direct competition. These help to recover the investment costs of designing, researching and developing the new products.

Conclusion

Since 1968 Intel has contributed to improving people’s lives, work and leisure. The company’s work is at the heart of the Internet, personal computing, mobile phones, games consoles and home entertainment systems. Intel products drive the technology we use in homes, hospitals, schools, offices, factories and airports.

Intel’s commitment to continual innovation and investment in research and development in product and manufacturing technology ensures competitiveness and growth. It also provides customers around the world with the latest developments.