In today’s rapidly changing business world, managers are repeatedly faced with a series of problems requiring a range of solutions. Although everyday problems are routine and relatively easy to solve, strategic problems are longer-term and require considerable judgement, intuition and experience. In order to solve such problems, therefore, the decision-making process needs to be based on hard data and informed analysis. It should also involve the freedom and flexibility for individuals to work together to make both critical and creative choices between a range of alternatives.

This case study focuses on a transportation joint venture between Adtranz, a manufacturer of railway vehicles and equipment, and Angel Train Contracts, a rolling stock leasing company. (Rolling stock is the term used to describe the stock of all types such as locomotives, coaches etc that run upon a railway.)

The challenge for this collaborative project was to develop high quality and affordable rolling stock which would meet the customer needs and requirements of a modern railway system. The joint venture needed to act quickly as the railway industry was concerned about the number of ageing multiple unit vehicles currently being used.

The background

An industry which is owned by the government is known as a nationalised industry or a public corporation. In 1979, the Conservative Government pledged to return selected publicly-owned enterprises to the private sector. Returning public corporations to the private sector is known as privatisation. The privatisation process for the Railway industry began with the 1993 Railways Act.

Initially, it was difficult to predict exactly what form privatisation would take and how it would affect the different areas of the railway industry. As a nationalised industry, the railways had suffered from insufficient investment. This meant there were very few new rolling stock programmes and many railway vehicles were becoming run-down.

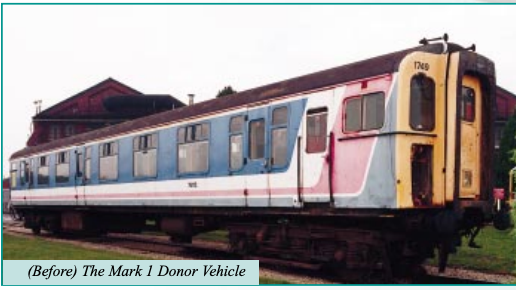

For example, there are nearly 1,400 Mark 1 multiple unit vehicles still in operation on the busy commuter lines in the south of England and many of these vehicles are more than 30 years old. The Clapham and Cannon Street accidents raised serious concerns regarding the safety of these vehicles and two major problems were highlighted – poor crash protection properties and slam doors. In an ideal world, these trains would have been replaced many years ago but little money was available for new trains.

Rolling stock leasing companies (ROSCOs) own and lease out vehicles and also purchase new vehicles; train operating companies (TOCs) lease out from ROSCOs and have their own operating staff (e.g. station staff, drivers cleaners and caterers.

Part of the privatisation deal with ROSCOs and TOCs involved an investment requirement in new trains.

However, leases were generally offered for seven years. Both rolling stock and train operating companies were committed to new investment but the short-term leases meant that if they were to reap the rewards from capital expenditure within the lifetime of their franchises, they would require new and high quality rolling stock quickly and at an affordable price.

Solving a problem

STEP 1 Recognise and define the problem

STEP 2 Identify the constraints and decision criteria

STEP 3 Identify alternatives

STEP 4 Evaluate the alternatives

STEP 5 Choose the best solution

The first stage in solving any problem is to recognise and define exactly what the problem is. In this case, the problem was that a large number of rolling stock vehicles needed to be replaced quickly with affordable new trains

which would improve safety and provide customers with the modern requirements of a passenger environment.

Once the problem has been recognised, it is necessary to identify the constraints of the potential solution. In other words, any solutions proposed must be able to be put into effect. In September 1996, Adtranz and Angel Train Contracts took up the challenge to solve the rolling stock problem by developing a practical and workable solution.

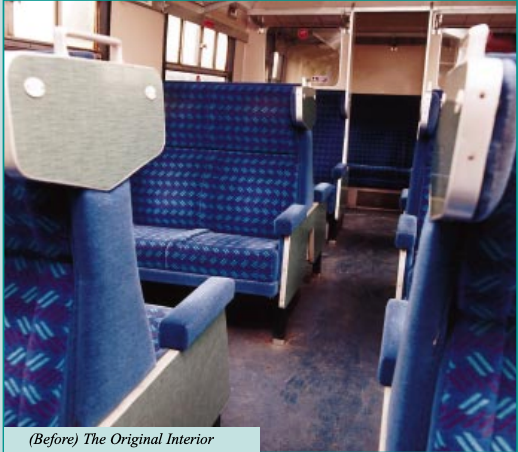

In normal circumstances, the solution would be simple, i.e. build new trains. In this case, however, there was an alternative – the Classic Concept. The Classic Concept is revolutionary although the idea behind it is very simple. Although the 1,400 Mark 1 multiple unit vehicles are the oldest still in service, there is plenty of life left in the bogies, traction package, brakes and under frames. One possible solution would therefore be to cut off the Mark 1 vehicle above the sole bar and then add a new, strong aluminium upper body. A new crashworthy cab could be put on each driving vehicle and bar couplers at the intermediate ends. The new aluminium upper body would incorporate a modern interlocked sliding door system. This solution would therefore address the safety problems of the current trains.

It was important to evaluate and compare this alternative solution against building completely new trains. Building new trains would take more

time and would cost significantly more. It would also require complete Railtrack approval and a period spent testing the new trains.

The Classic Concept meant considerable savings could be made – altering old trains was less costly than constructing brand new trains and Railtrack acceptance trials would be reduced. There would also be a shorter lead-time between orders and the deliveries of the Classic trains. (Lead time is the time between the order placement and its delivery). The process would help companies gain positive returns from investments and would be a better response to competition from other forms of transport.

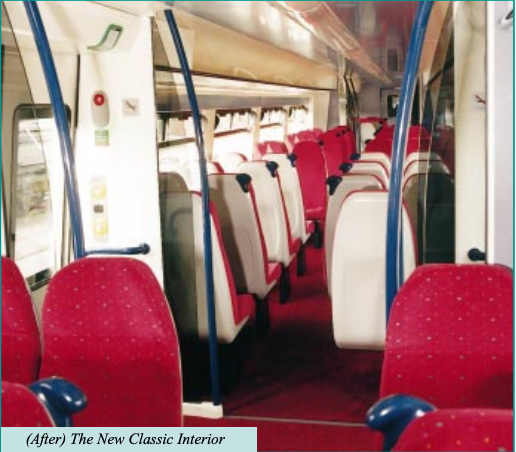

Customers would also benefit from the Classic Concept as these trains would be in service sooner and would have a new interior environment with higher safety specifications.

After careful evaluation, therefore, it was decided that the best solution was the Classic Concept. It would provide a safe vehicle with a minimum fifteen years’ operational life. Other safety benefits could also be added. For example, the interior could be brought up to the latest crashworthiness and fire standards. The wiring could be replaced and the driver’s environment greatly enhanced. All these benefits could be introduced at much less than the new vehicle price. So, the Classic Concept was the best solution in theory, but could it be done?

The partnership

Although Adtranz and Angel Train Contracts have different roles within the railway industry, they have shared goals. Both companies recognised that the old slam door Mark 1 rolling stock had a limited future and had to be replaced by 1st January 2003. The Classic would give passengers what would appear to be a new train. It would not only help to embrace more safety measures but would also deliver passenger improvements at a sustainable cost.

Product Development

Both companies began to work together to turn the theoretical concept into a real product. Having made the decision to pursue the project, it was important to assess the unique elements of the idea and identify any advantages it would provide. As a basis, the old vehicles were tested to assess performance requirements, tolerances, kinematics, weight etc.

A critical task was to integrate the new with the old, using standard products from generic concept vehicles forming part of the Adtranz current product platforms.

Computer-aided design (CAD) was used to develop the design for the vehicle. CAD works like an electronic drawing board, allowing complex two and three-dimensional shapes to be modelled quickly and accurately on screen. The next step was to build a prototype. A prototype is a key stage of development where a mock up is made to represent, as closely as possible, the final finished vehicle both internally and externally. As many production components as possible are incorporated at this stage.

This offers the potential of developing components and interfaces to reduce production line problems later. In addition, it provides the customer with a realistic vehicle for approval and passenger acceptance.

A Mark 1 vehicle was selected and the programme started. Throughout all the project phases, Adtranz and Angel Train Contracts involved Railtrack and Her Majesty’s Railway Inspectorate in detailed discussions. These guided the way through various Acceptance Processes which have to be undertaken before vehicles are allowed onto the railway network.

The project was managed by using Simultaneous Engineering Teams. (SETs). These are multi-disciplinary teams comprising Engineering, Procurement, Logistics, Finance, Manufacturing and Project Management in various combinations to achieve specific goals. This meant that various tasks and activities could be planned, mapped out and completed at the same time – thus reducing timescales. Developing the new Classic Concept took just one year from the first cut of the Mark 1 bodyside to the finished prototype.

Customer service has become a key element in building of trains. Customer service describes the one-to-one relationship between the supplier and the customer – the supplier being Adtranz, the customer being the train operating company. Providing new parts and total vehicle support allows the train operators to concentrate on their core business of running trains.

Adtranz today operates in a completely different environment to that of pre-privatisation. For a manufacturer to be successful there are four key elements:

R Reliability

A Availability

M Maintainability

S Safety

These are important facets which have to be considered at all stages of the ‘cradle to grave’ service now offered by Adtranz.

Within the production area, Adtranz recognises the importance of customer focus and good customer service at all levels within its business. There are customer focus rooms where employees can analyse aspects of operations and discuss the contract. This represents a significant development involving all employees with decision-making at every stage.

Benefits of the classic

A new cab layout was designed with driver comfort and ergonomics as a priority. Ergonomics is the science which deals with the interaction of individuals, objects and the environment or system in which they operate. The new interior has a flexible seating layout which could be adapted to the needs of each train operator. Windows are double-glazed and a combination of underseat and bodyside heaters provides a comfortable interior environment.

Safety benefits of the Classic include:

- improved crashworthiness

- sliding doors

- safer interiors

- improved fire standards

- replacement of wiring and pipework

- improved driver environment.

For the passengers, the Classic offers:

- a spacious interior

- more and better quality seats

- a wheelchair area

- a toilet suitable for the mobility impaired

- a passenger alarm system

- a modern exterior

- destination indicators.

Testing of the prototype was particularly important and the vehicle was subjected to the rigorous set of static loads required by Railtrack’s Railway Group Standards. These are the requirements specified by Railtrack for the acceptance of new and modified vehicles. The new vehicle passed with flying colours which meant the project could proceed and achieve the bulk of Acceptances.

Before launching any new product, it is important to carry out detailed research. In this case market analysis was used to provide more detailed information on the commercial aspects of the project. It was particularly important to find out how consumers would react to the Classic train. The prototype was taken to Victoria station in London and potential passengers were allowed to walk through the vehicle. More than 2,000 questionnaires were returned, with over 84% being positive about the new vehicle. Comments were helpful in further developing the product.

The tender

The Classic train has been developed to provide Adtranz with a competitive advantage in gaining contracts for the refurbishment of Mark 1 vehicles. Having developed the Classic design and proven the concept using the prototype vehicle, Adtranz and Angel Train Contracts needed to win a production order.

To do this, the Classic concept needed to be costed accurately so that a price could be put forward to a potential customer. The cost elements included setting up the production line, buying in the parts, manufacturing labour and overheads.

This is all put forward in a tender which is a proposal to carry out work or provide services. Given the large number of vehicles requiring replacement, Adtranz had the ideal product platform base to submit a cost-effective tender for each contract to meet the needs of each of its customers.

Building a competitive advantage

The Classic has been developed at a time of radical change in the railway industry. It is the result of careful planning, research and development by Adtranz and provides a cost-effective, consumer-friendly solution. Although

the units look new, the Classic is an environmentally friendly solution as it is produced from recycling parts of existing trains. Adtranz has made best use of existing resources and is able to respond to market changes quickly.

The Classic is also a concept which is equally applicable to other vehicles or to trains in overseas markets.

In a competitive environment such as the railway industry, it is important to be first with innovations and product developments. Work for the Classic prototype helped Adtranz move ahead of its competitors – providing a differentiated and better product which built on the organisation’s advantages. The Classic is a new product platform which, by reducing lead-time from order to delivery to between nine and twelve months, has provided Adtranz with a way of responding flexibly and quickly to its customers.

Conclusion

The Classic is a clear demonstration of a different product concept which reflects a new approach in a changing industry. It has involved:

- the proactive development of a new product to meet the needs of a potential customer

- the side-by-side collaboration of Adtranz and Angel Train Contracts on an innovative development to meet a specific customer need.