Making sure that government, businesses and households have secure supplies of energy is a huge commitment. Engineers working for energy supply companies must make sure that this commitment is met 24 hours a day, 365 days a year. This case study shows how the engineers who work for one of the UK’s major energy businesses, RWE Npower, are involved in securing energy supplies and in the management of risk.

Risk lies at the core of any enterprise activity. Businesses therefore have to manage risks every day of the week, for 52 weeks in the year. Successful management of risk involves getting the balance right between risk and other factors such as cost and return.

Engineers deal with real problems involving real materials and projects. The work of an engineer is varied and stimulating.

Engineering is an exciting career. For example, graduate engineers working at a power station will not only work with computer models, but also will help to run projects, control the materials, equipment and plant. This is engineering on a grand scale. Engineers working for RWE Npower are trained at all levels to combine technical skills with commercial knowledge. To be successful they need to understand the business implications of the decisions they make.

RWE Npower’s operating environment

It is important, when assessing risk, to be aware of the operating circumstances of the business. The energy industry is at the heart of any modern economy. Electricity and gas suppliers provide the essential power supplies for industry as well as for our homes. They seek to keep energy costs low while operating for 365 days a year.

RWE Npower is an integrated energy company. It is the third largest supplier of electricity and gas in the UK, through its Npower brand, and one of the largest electricity generators. It is also part of the larger RWE Group which is one of the largest European energy utilities. Its main markets are the UK, Germany, and Central Eastern Europe (including Hungary and the Czech Republic).

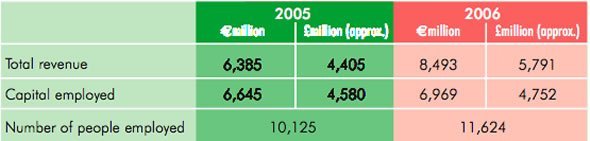

RWE Npower not only provides and supplies to the national grid (electricity) and to the national transmission system (gas), it also provides a huge economic contribution. This is illustrated by the figures for turnover, capital employed and employment.

These figures are a snapshot view of the scales of RWE Npower’s operations.

As one of the UK’s leading companies, RWE Npower contributes to the economy by:

- providing exciting jobs with prospects

- selling energy to households and businesses, enabling a better standard of living

- investing in huge capital projects such as the building of power stations (including the development of alternative power supplies such as wind farms and biomass plants)

The most visible face of the company is its huge power stations such as those at Didcot in Oxfordshire and Littlebrook in Kent. These power stations supply energy to the national grid. The energy industry is very competitive. It is a deregulated market in which companies are free to compete in supplying gas and electricity. RWE Npower places a strong emphasis on sustainability.

Sustainability means using existing resources so that supplies of natural resources and raw materials are passed on to future generations. For RWE Npower sustainability involves creating energy supplies with less pollution. This is a major consideration in modern engineering decisions. A major aspect of energy efficiency is that of seeking the best possible ‘green solutions’. A ‘green solution’ is an environmentally friendly one. In this way RWE Npower engineers and other employees play a significant role in working towards a sustainable future.

Health and Safety underpins every action that RWE Npower takes. For example, the company has its own safety system based on years of experience of managing safety issues. RWE Npower sells its expertise in providing safe and sustainable energy supplies to other businesses around the world. RWE Npower is involved in activities all through the supply chain of electricity and gas.

Types of problem-solving

Business problem-solving typically fits into three main categories:

- Deviation problems. This is where a business is falling short of its expected targets. For example, a power plant is contracted to supply 2,000,000 kilowatts of power to the national grid and is falling short of this by 5%. The problem-solving involves getting capacity back up to the required level.

- An improvement problem. The business is doing well but wants to do better. For example, are there more efficient ways of generating electricity or producing electricity from alternative fuels?

- An open-ended problem. There are no textbook answers to these problems. We use the term ‘thinking outside the box’ to describe the ways of thinking that are required here.

The ‘box’ refers to thinking in standard ways. Thinking outside the box involves looking for alternative ways that involve new solutions and ways of tackling problems. Thinking outside the box is where creative thinking is required. Modern engineers need to show imagination. An imaginative idea can save a company millions of pounds and lead to better solutions for customers.

At RWE Npower, engineers at all levels are expected to handle these three types of problems every day of their working lives. For deviation problems and improvement problems, there will often be tried and tested techniques. Typically these techniques involve teamwork. Teamwork is essential for effective decision-making. Groups of engineers with different skills come together to shed light on problems and issues and to come up with improvements. In a team there will be engineers with different technical knowledge and experience. These will include mechanical, electrical and civil engineers, and computer specialists.

Teamwork involves good communication skills, particularly the ability to listen to others’ ideas. Being able to identify the route cause of the problem and understand the symptoms is essential. Working in teams creates a buzz of excitement. Engineers enjoy solving problems. They like to be creative. Working together allows them to bounce ideas off each other. Some of the solutions RWE npower engineers have come up with have saved the company millions of pounds.

Creative problem-solving

In business, there is typically a direct relationship between risk and reward. The bigger the risk you take, the greater the possibility of making a high return. The reverse side of this is that high risks can also be associated with spectacular failure.

Engineers working for RWE Npower need to understand the commercial implications of the decisions they make. The best decisions will be those that provide good technical solutions while at the same time are commercially successful. Learning to manage risks is important. Decisions taken must be in line with other priorities such as safe working. At RWE Npower, health and safety is the number one priority.

Creative problem-solving involves dealing with problems for the very first time.

While there are tools and techniques to help find solutions, engineers will need to be creative. They need to decide what methods to use and ultimately how the problems will be solved.

At senior management level, RWE Npower has engineers with responsibility for running very large units such as a power station. These senior managers are continually provided with information about every aspect of the performance of the plant. They receive advice and information from a range of specialists. The sorts of problems they encounter include what to do when a weakness is spotted in materials. For example, the giant turbines which power the generators can develop tiny defects over time. The turbines can weigh more than 250 tonnes and rotate 3,000 times a minute. These defects are actively managed and carefully monitored to ensure they do not deteriorate to present a potential safety risk.

When a plant manager is notified that tiny cracks have been found in the turbine, then he or she must come to a decision very quickly. The options are:

- Shut down part or all of the plant and start repairs. In the middle of winter, this could prove to be very costly. When demand is at its peak this could lead to losing supply contracts worth £2 million per day.

- Take advice from specialist engineers to check whether it is still possible to continue operating while carefully monitoring the weakness. Specialist fracture engineers would need to prove that, if they continued to run operations, the impact on the materials would remain within safety limits. Repairs would then be made as soon as possible.

- Do nothing. (At RWE Npower this is not an option.)

Managers will only consider options that do not involve a health and safety risk. Once they are satisfied that this is the case they will consider commercial criteria. The best solution will be the one that fully meets the requirements of customers while at the same time yielding the optimum financial return.

Creative problem-solving at graduate level

It is not only top level managers that make important commercial decisions. RWE Npower employs graduate engineers straight from university. They contribute to the decision making processes from the start. Typically their salaries start at about £25,000. They receive training and development throughout their career at RWE Npower. They are encouraged to think for themselves and to place a high importance on commercial criteria in making decisions.

For example, a decision made by a graduate engineer saved the company millions of pounds. One of the problems in running a power station is that deposits accumulate on the many kilometres of pipes in the giant power station boilers and they take a long time to be removed. The deposits need to be removed so that the thickness of the metal in the pipes can be checked. Over time the pipes wear down and will eventually need to be replaced.

Recently a RWE Npower graduate engineer developed a specialised measuring probe. This made it possible to test the thickness of the pipes without the need for removing the deposits. The probe made it possible to check instantly on the thickness of the pipes. This gives managers much more up-to-date data about how safe the equipment is so that repairs can be planned in the most economical way.

Conclusion

The success of the UK economy depends on having secure and efficient energy supplies. Each day the challenge is increasing as resources become more scarce. For example, the world’s oil and gas reserves are running out. At the same time much of the capital plant that makes up the national grid and many older power stations needs replacing. This creates immense challenges and opportunities for today’s graduate engineer. These are exciting times to get involved in engineering.

Engineering provides great prospects for suitably qualified applicants.

The engineers of today and tomorrow are people who make important and sometimes vital decisions. They have to be problem-solvers who enjoy working with people in teams and with real problems related to materials, processes and equipment. The decisions they make affect our lives. The excitement of a career in engineering comes from knowing that you will develop solutions to problems which haven’t yet been thought of. As you can see from this case study, good creative decision making can save millions of pounds and improve environmental and safety performance.