The Dyson Dual CycloneTM is the first breakthrough in vacuum cleaner technology since 1901. In 1979, James Dyson noticed that his bag vacuum cleaner only picked up dirt properly with a new bag and that it lost suction rapidly as the bag filled. The vacuum cleaner bag needs to collect the dust, but allow air to pass through via tiny pores, in order to maintain airflow and therefore suction. In fact, the dust quickly clogs these pores and blocks the airflow. Because the air is blocked, the cleaner’s suction is reduced very quickly.

So James Dyson set out to design a vacuum cleaner that worked better. five years and 5,127 prototypes later, the world’s first vacuum cleaner with no bag and no loss of suction arrived. Any product which is clearly different from those of its competitors is said to be differentiated. James Dyson spent two years trawling the UK and Europe looking for someone to license the product. He finally sold his machine under licence in Japan where it became a status symbol, selling for £1200 apiece.

A licence is a commercial contract, which allows an overseas manufacturer to produce a product and use a patent or brand name. Using the income from this licence, James focused on his plan to manufacture a new model in Britain. He started in his workshop at his house in Bath, together with a small team of young design engineers. In 1993, 15 years after he had the initial idea, he opened his own research centre and factory in Wiltshire, producing the DC01 – the first in the Dyson Dual CycloneTM range of vacuum cleaners. Throughout this entire process, James Dyson and Dyson Appliances concentrated on planning for the long term rather than giving in to the apparent attractions of short-termism.

Investments

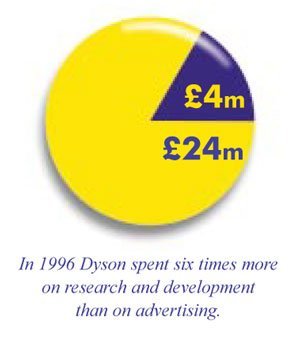

Dyson firmly believes that a company’s profits should be invested back into research and development, rather than continuing to sell an ordinary product only on the strength of the way it is advertised or marketed. For example, spending money on a new advertising campaign may be quite a good way to encourage a lot of people to buy something very quickly, but if they discover that the product itself is not of high quality, or does not fulfil their needs, they will not buy it again. This means the company will have a short burst of profits for a relatively small expenditure, but will not be profitable in the long-term.

A consumer will be encouraged to buy and keep buying a company’s products if they know from experience that they work well and do exactly what they are intended to do. In addition, Dyson aims to design products that are revolutionary and work better. To achieve this a company needs to spend a lot of time investing in research, testing and development to discover exactly what the consumer needs and design the best solution. At Dyson, this idea extends to every part of the development process: design, engineering, patenting, sales, customer care and after sales.

The invention of the first Dyson Dual CycloneTM vacuum cleaner was only possible because of the time and money which James and the team invested in the development of the DC01, which was protected by patents so no one could copy the revolutionary idea.

Developing a new Dyson

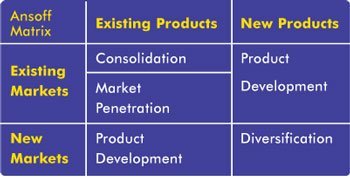

After the success of the DC01 upright and DC02 cylinder cleaner, Dyson wanted to maintain its market leading position with more, innovative products. The Ansoff matrix below shows that a company should keep changing both in its target market and in its products. Existing products can be introduced to new markets, overseas for example, or a new product can be developed which will appeal to a new market sector.

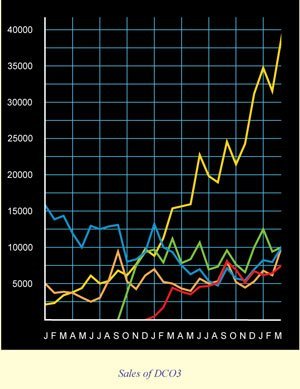

One of the first results of Dyson’s research and development was the launch of the DC03, a new upright vacuum cleaner. DC03 was based on existing products (DC01 and DC02), but with further innovation, and made to appeal to a new market. The Ansoff matrix classifies this kind of activity as product development. DC03 took a long time to develop from the idea stage to a product which could be sold through electrical retailers. This new product was to be a response to requests from consumers of the DC01 and DC02, ideas from the design team and the activity of the national and international market-place.

A questionnaire was sent out to existing customers about their Dyson, the other appliances they used and their lifestyle. 72,000 replies were sent back, along with over 5000 additional letters. In addition, everybody who works at Dyson makes their own vacuum cleaner and uses it at home so all staff have input about ways products could be changed or developed. They discovered, for example, that some consumers had a particular need for a vacuum cleaner which was very light and slim line. Customers still wanted to retain the thing they enjoyed about Dyson: the clear bin, integral hose and, most importantly, the fact that it does not lose its suction.

Competitive strategy

The vacuum cleaner also had to answer the current concerns of consumers about the air filtration of vacuum cleaners and how to clean all types of floor surface. These became some of the drivers behind the new design.

Dyson needed to make a thorough investigation of other vacuum cleaners available on the market, to assess where DC03 may fit in. Using varied resources such as trade magazines on the electrical industry, the Internet, in-store promotions and competitor literature, they were able to assess the impact the DC03 would have.

At Dyson, market research is not the main driver behind product development. For example, market research indicated that consumers perceived a bigger motor meant a better cleaner. However, Dyson did not give in to pressure to fit a bigger motor. Dyson fitted the DC03 with a smaller, lighter, energy saving motor and engineered the machine to be more efficient. The airflow in DC03 has been designed so that a smaller motor is as effective as a larger one. Engineering research and development, and sometimes the intuition of the design engineers, provide Dyson with a competitive edge.

Engineering development

Using the information from consumers, as well as their own experiences and ideas, Dyson’s in-house design engineers aimed to ensure every detail of the DC03 made vacuuming better for the consumer. All three models in the range are based on Dual CycloneTM technology, but the DC03 upright builds upon DC01 upright and DC02 cylinder models and further improves the design of a vacuum cleaner. The design process was based on iterative development which is slow and painstaking, with testing at every stage. It is the best way to ensure each part of the product is as good as it can be.

Designing at Dyson is a complex process. At all times designers have to balance ideas about how it would function, its performance, safety, reliability and cost. If ideas about one of these change then the whole design has to change. A variety of prototypes such as sketches, breadboard, foam and rapid prototype models help the design engineers test the product and realise its functions.

The engineering department decided to invest in a new computer package that would enable them to draw in 3D (3 dimensions) rather than only 2D. As well as allowing more scope for designing on the computer before a model was made, the computer pictures in 3D meant there was less chance their designs would be misinterpreted by the toolmakers. It required a large outlay at an early stage but it would mean a better product in the long run. They then invested in 3D prototype modelling machines to run with the new computer package. This package directly interprets the 3D picture on a screen into a real model.

Customers’ needs and desires

Once the DC03 had reached a working stage, and its new technology had been patented, the marketing research department decided to find out what consumers thought of it by setting up focus groups. Carefully selected groups which included a mix of ages, sexes, and backgrounds, were given a DC03 to use at home and a questionnaire to answer. They were then invited to talk in groups about their findings.

The emphasis throughout the whole development process is on ideas, testing and analysis. This takes time and financial investment but Dyson believes this commitment is crucial for the growth of the company, consumer loyalty and consumer satisfaction.

Patents

A patent gives the patent owner the right to stop someone else from making or selling the patented product. If the patent covers a part of a machine like a vacuum cleaner, then the patent gives the owner the right to stop other people from making or selling any vacuum cleaner including that part. The monopoly can last for up to 20 years from the date of filing the patent application. Without a patent to protect a product, anyone who wants to can take the same idea and use it in their own products. This can be very unfair, especially if the first person to think of the idea had to spend a lot of time, effort and money developing the product to make it work and to put it into production.

Getting a patent can take a long time and be very expensive. Patents are only effective in the country in which they are granted so you have to protect your idea in each country in which you want to have the right to stop other people from using your idea. However, once you have a patent, you have a weapon with which you can build a commercial lead against your competitors. Dyson tries to protect any inventions made during the development of its machines. No less than fourteen new inventions were identified and covered by patent applications before the DC03 was launched in January 1998. These inventions were all made during the course of the development of the DC03 which is, of course, also protected by the patents covering the original idea of the cyclonic separation system. The original patents date back to 1981. The overall appearance of the DC03 was also protected by a Registered Design.

The patent applications filed in respect of the fourteen inventions made during the development of the DC03 will probably mature into at least 100 patents over a period of a few years. Each patent will need to be maintained and the costs will be high. However, it means that competitors will be unable to take Dyson’s ideas and put them into their machines. In this way, Dyson maintains its competitive advantage in the marketplace.

Launching DC03

The DC03 Dyson Dual CycloneTM vacuum cleaner was launched in January 1998. It uses the Dual CycloneTM technology which ensures that the cleaner does not lose suction as it is used, plus it is light, slimline, has two HEPA filters, and a brushbar that can be switched on or off enabling the consumer to vacuum different surfaces.

Within just two months of launching the DC03, it had captured over 13% of the total vacuum cleaner market in the UK. The years of hard work had paid off: DC03 answered the needs of a specific type of consumer perfectly. DC03 had been more than two years in the making. When DC03 reached the shops, the benefits of investment of time and money became very plain.

Conclusion

Dyson’s investment for the long-term continues even after the product has been sold to a customer. There is support readily available for Dyson customers if they need advice or help with their vacuum cleaners. Dyson makes every effort to ensure that customer care creates the minimum of fuss and expense for the consumer – it is a key part of Dyson’s philosophy to invest time in treating its customers well.

Most appliance companies allow electrical stores or service agents to repair machines or provide spare parts, but this is not always convenient for the customer. Dyson ensures that customers receive the best advice and help all the time. They can phone a helpline and speak to an operator who can advise them on how to maintain their cleaner, sell them any accessories, or arrange to have the cleaner repaired. Dyson employs telephone operators and service engineers to ensure this operation runs smoothly. The lines are open seven days a week from 8am to 8pm, and fax and email can also be used. A courier collects the cleaner from the customer’s home, and delivers it back, serviced and repaired within three days.