Nissan Motor Manufacturing UK Limited (NMUK) is the UK’s largest car manufacturing plant which is located near Sunderland. In terms of the number of cars produced annually for every person employed, it has been Europe’s most productive car plant for the past seven years.

This achievement is no accident. It was designed and planned for from the outset. This case study looks at some of the key elements that have contributed to Nissan’s success.

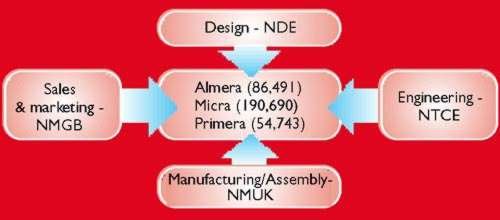

NMUK handles all aspects of the manufacturing/assembly of the Primera, Micra and Almera ranges:

By the end of 2003, NMUK produced 331, 924 vehicles, over 70% of this output was exported to 55 markets worldwide.

As well as NMUK, Nissan operates four other UK sites.

Nissan Design Europe (NDE) supports design teams responsible for aspects such as colour and trim design, digital design, modeling, design strategy and communications. The main focus is on design for the European market, but this Nissan sub-division also contributes to global design.

Nissan Technical Centre Europe (NTCE) is in Cranfield. This is a centre of excellence for the design and development of vehicles for Nissan’s European operations. NTCE is part of Nissan’s worldwide network of development centres (in Japan, USA and Europe). Each centre focuses on cars prepared for specific markets; Cranfield concentrates on European customers’ requirements.

Nissan Motor (GB) Ltd (NMGB) is the sales & marketing division for the UK. In ten years the company has sold over 1 million vehicles to UK buyers. The product range caters for different consumer needs, and includes:

- Micra (small, economical town car)

- Almera, Tino (medium sized multi passenger vehicle: MPV)

- Primera (saloon, hatchback and estate)

- X-TRAIL, Terrano, Patrol GR (4 X 4 vehicles)

- A complete range of Light Commercial Vehicles (LCV) – Kubistar, Primastar, Interstar, Terrano Van, Cabstar and Pickup.

Lutterworth Parts Distribution Centre is the Alliance (Nissan and Renault) parts distribution and storage facility which delivers over 135,000 parts per week to Nissan and Renault dealerships throughout the UK and Southern Ireland.

Why locate in Sunderland?

One key decision with a car plant is where to locate it. For its UK factory, Nissan chose in 1984 a 300 hectare former airfield near Sunderland. Sunderland’s attractions included:

a) Skilled labour force

Manufacturing has a long tradition in the area. A decline in other local manufacturing meant that skilled labour was readily available.

b) Communications

Sunderland has good road and rail links to all major UK areas. This makes it relatively easy to bring in supplies from 105 separate UK component and sub-assembly suppliers, and also to distribute completed vehicles. A nearby deep water port (Port of Tyne) gives ready access to export markets and for the import of vehicles to the UK.

c) Government support

The government provided financial and other incentives to manufacturers who set up in an area where employment opportunities had reduced sharply and new jobs were needed.

Since 1984, Nissan has increased the scale of its Sunderland operation; almost 3.5 million cars have already been made.

Nissan | Planning for quality and productivity

Production

Car assembly is a complex operation with many components requiring skilled assembly. For example,

That’s a crude indication of what is involved. Management are particularly keen to monitor total machine-hours and total labour-hours that each vehicle requires.

So far, Nissan has invested over £2.1 billion in the Sunderland site, taking its production capacity to 500,000 vehicles per year.

Production methods must be able to produce what customers want, in the quantities customers require, at a price consumers are willing to pay, and at a cost that yields a profit to the business. That means that being efficient is vital to success.

In some industries it is possible to carry out individual job production to meet a particular customer’s request e.g. a wedding dress, a birthday cake, a fitted kitchen. However, very nearly all of the world’s car manufacturers mass produce standard models, with individual consumer choice being accommodated by offering various colours, interior designs, and optional extras within a limited flexible production process. People can still personalise their cars further e.g. by choosing a particular car registration or accessories.

In pursuit of high output at low average cost, car manufacturing typically uses a continuous flow production method, where sub-assemblies are brought together in a final assembly area. This is the most cost effective and efficient method of production and the speed of the final assembly line can be adjusted to match consumer demand. If demand picks up, the production line can be accelerated, within predefined limits.

At NMUK, the production flow draws on three main production shops, as well as support areas. The three main shops are:

- Body assembly

- Painting

- Final assembly.

Supporting manufacturing areas are:

- Press shop – produces panels for the vehicles

- Plastics shop – makes bumpers (fenders) on site

- Castings shop – makes engine parts e.g. cylinder heads

- Engine shop – assembles engines, installs oil, coolant fuel

- Axle plant – produces axles that are joined to engines in final assembly.

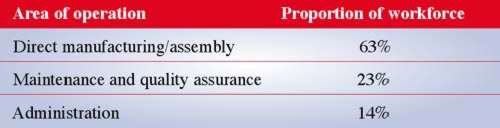

Widely different processes generate different jobs across three main broad areas.

The machinery is scheduled to work at a given level although when demand requires it; there is flexibility in regard to both the machinery and the workforce of 4,300. At the moment, with a two-shift pattern, NMUK has a total production capacity of around 360,000 units/year – a third shift can be introduced which would take production up to 500,000 units/year if and when required.

Nissan | Planning for quality and productivity

Flow production

Nissan’s Sunderland plant is technically highly advanced. It uses sophisticated robotics and computer integrated manufacturing techniques to create a carefully monitored production process that reduces errors to an absolute minimum.

Automated machines can only do so much however; the human element remains vital. Organising an effective flow of production at Nissan has involved developing a way of doing things and an attitude towards work based on giving responsibility to employees at every step. This approach raises employees’ morale, and reduces absenteeism, which could severely impact on continuous flow production.

Nissan expects and requires its employees to become multi-skilled decision makers. Most employees also want that for themselves. Reaching that goal involves:

- Training employees to develop their skills

- Encouraging them to make decisions

- Organising employees into participative teams

- Developing open-channel, multi-directional communication systems

- Placing quality at the heart of flow production

- Flexible working practices

- Providing the employee variety within his/her role.

The open communication policy includes daily face to face meetings between management and employees, a company council, employee surveys, and employees having ready access to the company’s intranet system.

The emphasis placed on ‘going for quality’ means that each employee is responsible both for their own work and the standards of their co-workers. By ensuring management recognises that individuals have this control results in everyone taking the culture on board.

‘Going for quality’ emphasises ‘building good quality in’ rather than ‘inspecting poor quality out’. Each employee controls quality by checking that the previous job has been done properly.

Total Quality Management

Total Quality Management (TQM) is a key feature of Nissan’s way of working. TQM involves making customer satisfaction top priority. Given this goal, everything the organisation and its people do is focused on creating high quality. To achieve this, Nissan has to:

- Understand customer requirements

- Consider the processes involved in providing quality, not just the end result

- Prioritise and standardise tasks to deliver quality

- Educate all employees to work in this way.

In practical terms TQM involves:

- Identifying customers and their requirements

- Establishing and using objectives (targets) for all areas of activity

- Basing decisions on researched hard facts rather than on hunches

- Identifying and eliminating the root causes of problems

- Educating and training employees.

TQM is an ongoing process; a way of thinking and doing that requires an ‘improvement culture’ in which everyone looks for ways of doing better. Building this culture involves making everyone feel their contributions are valued and helping them to develop their capabilities.

A cycle of Plan, Do, Check, Action becomes part of every employee’s thinking, because it represents Nissan’s way of working.

Just-in-time technology

With a just-in-time approach, specific vehicles and their components are produced just-in-time to meet the demand for them. Sub-assemblies move into the final assembly plant just as final assemblers are ready to work on them, components arrive just in time to be installed, and so on. In this way, the amount of cash tied up in stocks and in work-in-progress is kept to a minimum, as is the amount of space devoted to costly warehousing rather than to revenue-generating production. Nissan’s just-in-time process depends not on human frailty but on machine precision.

Every vehicle is monitored automatically throughout each stage of production. A transponder attached to the chassis leg contains all of a vehicle’s production data e.g. its required colour, specification and trim. This triggers sensors at various points along the production line thus updating the records.

When, for example, the transponder sends a message to the production system at a supplying company to produce a seat in a particular colour and trim, this triggers the relevant response and a seat to the required specification is produced. Further along the production line the specifically produced seat arrives to meet the vehicle to which it belongs – just in time.

The importance of training

It is vital to train people to work in such a hi-tech industry with such sophisticated quality systems. NMUK’s training department conducts a training needs analysis to assess individual employees’ needs and to organise training programmes.

The department concentrates on five main areas:

1. Technical development – e.g. teaching skills relating to robotics and electrics, plus the required knowledge e.g. wiring rules/regulations.

2. People development – identifying employee needs and ambitions; providing courses to help personal development e.g. in team building and communication skills

3. Understanding processes – workshops covering safety, production operations etc

4. Computer skills and graduate training – from basic to highly technical

5. Trainee development – courses for graduate trainees ranging from accountancy to team building.

Kaizen

Nissan is famously associated with ‘Kaizen’ or continuous quality improvement. Nissan states: ‘We will not be restricted by the existing way of doing things. We will continuously seek improvements in all our actions.’

Kaizen can be applied everywhere, any time, any place. It can involve the smallest change in everyday working practice as well as a major change in production technology. Typically these improvements are initiated by teams of employees sitting down together and sharing ideas for improvements. Small steady changes are maintained to make sure that they actually work. No improvement is too small. Everyone at Nissan is responsible for thinking about the current way of doing a job and finding a better way of doing things.

Kaizen improvements can save:

- Money

- Time

- Materials

- Labour effort

as well as improving quality, safety, job satisfaction, and productivity.

Kaizen permeates the NMUK suggestion scheme, which offers not financial or individual rewards but items that benefits the whole team e.g. a microwave for the staff kitchen, a pool table for the canteen.

Conclusion

Productivity levels at Nissan’s plant in Sunderland, and the quality of final production there, have not happened by chance or good fortune. They stem from an all-embracing approach to a production process, designed to bring out the best in both people and machines. It continues to be conspicuously successful.